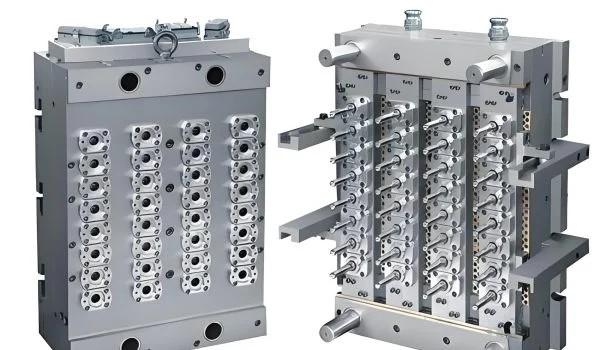

In the world of injection molding, efficiency and cost-effectiveness are paramount. One of the key methods used to achieve both is the multi-cavity mold. This type of injection mold allows for the simultaneous production of multiple identical parts in a single cycle, significantly improving the throughput and cost efficiency of injection molding processes. Understanding the concept, design, and advantages of multi-cavity molds helps optimize production processes.

What is a Multi-Cavity Mold?

A multi-cavity mold is a type of injection mold designed to produce multiple copies of the same part in one injection cycle. Unlike a single-cavity mold, which produces only one part per cycle, a multi-cavity mold is designed with multiple cavities (molds) to accommodate the simultaneous creation of multiple parts. The number of cavities in a mold can vary, and a mold could have anywhere from two to dozens of cavities, depending on the complexity of the part and the molding machine’s capabilities.

Types of Multi-Cavity Molds

- Two-Cavity Molds: These molds are the simplest and often used for moderate-volume production. They are ideal for parts that are relatively simple and have similar size and shape.

- Four-Cavity Molds: More commonly used in medium- to high-volume production runs, these molds help increase productivity without requiring a significant increase in cycle time.

- Family Molds: A family mold includes different but related parts in the same mold. While each cavity still produces a different part, all the parts are typically produced in the same cycle. This setup is ideal for producing multiple parts that share similar features, such as connectors or assembly components.

- Hot Runner Systems: Multi-cavity molds often use hot runner systems to manage the flow of molten plastic to the cavities. Hot runners help maintain consistent temperatures and improve the overall quality of the final product.

Key Components of a Multi-Cavity Mold

1.Mold Base: The mold base is the foundation of the multi-cavity mold. It houses all the cavities and the associated components, like the runners, sprues, and ejector systems.

2.Cavities: These are the actual molds that define the shape of the part. A multi-cavity mold has multiple cavities arranged to allow for efficient use of space and material.

3.Sprue and Runner System: The sprue connects the injection molding machine nozzle to the mold cavities. The runner system distributes the molten plastic to the individual cavities, ensuring equal filling.

4.Ejector System: After the parts are molded and cooled, the ejector system helps to remove them from the mold.

5.Cooling Channels: Efficient cooling is crucial in multi-cavity molds, as uneven cooling can lead to variations in part dimensions. Cooling channels are strategically placed around the cavities to help maintain uniform temperatures.

Benefits of Multi-Cavity Molds

1.Increased Production Efficiency: The primary advantage of a multi-cavity mold is the ability to produce multiple parts in one cycle. This results in faster cycle times, reduced labor costs, and ultimately higher production efficiency.

2.Cost-Effectiveness: By producing multiple parts at once, manufacturers can reduce the per-unit cost. The cost of creating a single injection mold is spread across many parts, which makes multi-cavity molds ideal for high-volume production runs.

3.Consistency and Quality: Because all parts are produced under the same conditions (temperature, pressure, and time), multi-cavity molds often result in parts with more consistent quality, reducing the need for rework or quality control issues.

4.Lower Energy Consumption: As multiple parts are made in one cycle, the overall energy consumption per part is often lower, making it more sustainable and cost-efficient.

5.Optimized Use of Materials: With multiple parts being produced simultaneously, the material used for each part is optimized, leading to better material efficiency and reduced waste.

Challenges in Multi-Cavity Molds

1.Complexity in Design: Designing a multi-cavity mold requires careful consideration of factors like part geometry, material flow, cooling, and injection pressure. This makes the design process more complex and often requires more advanced simulation and testing.

2.Increased Initial Investment: Although multi-cavity molds reduce per-part costs in high-volume production, the upfront cost of designing and building a multi-cavity mold can be significantly higher than that of single-cavity molds.

3.Balancing Cavities and Mold Pressures: Ensuring uniform pressure distribution across all cavities is crucial for preventing defects like flash, short shots, or warping. Achieving this balance requires precise mold design and tooling.

4.Mold Maintenance: As multi-cavity molds experience more wear and tear due to their complexity and the large number of moving parts, maintenance becomes a critical factor in keeping the mold operational. Regular inspection and maintenance are necessary to prevent costly downtimes.

Design Considerations for Multi-Cavity Molds

1.Mold Balance: One of the most critical design factors is ensuring that the mold is balanced, meaning that each cavity receives an equal amount of material at the same pressure. Uneven material distribution can lead to differences in part quality, size, and shape.

2.Gate Design: The design of the gate, which is the point where the molten plastic enters the cavity, plays a vital role in ensuring even filling. Gates need to be carefully positioned to avoid short shots, air pockets, and material overflows.

3.Cooling Systems: Since multiple parts are produced at once, efficient cooling systems must be incorporated into the mold design to prevent uneven cooling. A uniform cooling time across cavities ensures that the parts are properly solidified and dimensionally stable.

4.Ejection Mechanism: The ejection system must be capable of removing multiple parts simultaneously without causing damage. Ejector pins or plates are typically used, but their design needs to account for the number of parts being ejected and the complexity of the mold.

5.Mold Material: The material used for the mold must be durable enough to withstand the high temperatures and pressures of the injection molding process. Materials like steel or aluminum are often used for multi-cavity molds, depending on the production volume and part complexity.

Multi-cavity molds are essential for high-volume injection molding production, offering significant advantages in terms of efficiency, cost reduction, and part consistency. While they come with design challenges and higher initial costs, their ability to produce multiple parts simultaneously makes them a valuable tool in optimizing production and ensuring that parts meet the required quality standards.