A mold trial is a crucial step in the injection molding process, often occurring after the initial mold design and fabrication. It is essentially a test run that allows manufacturers to evaluate how a mold performs under real-world conditions before beginning full-scale production. Mold trials help identify potential issues early, ensuring that the mold can consistently produce high-quality parts with minimal defects.

In this guide, we will explore what a mold trial is, why it’s essential, and how to conduct a successful trial in manufacturing. Whether you’re new to the industry or refining your processes, understanding mold trials is critical for optimizing production efficiency and quality.

What Is a Mold Trial?

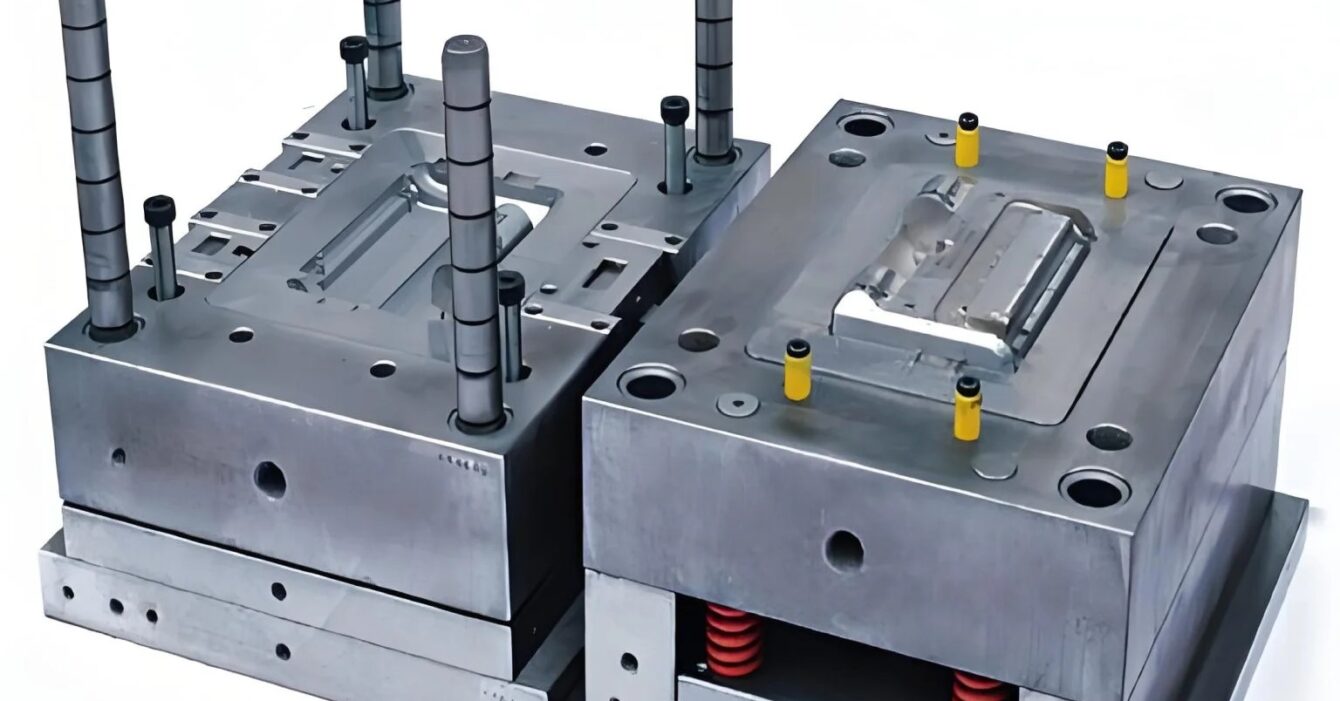

A mold trial, also known as a trial run or first shot, refers to the initial attempt to produce a molded part using a newly designed and manufactured mold. During the trial, the mold is loaded into the injection molding machine, and material is injected under controlled conditions to test the mold’s performance. The primary goal is to determine whether the mold can produce parts that meet the required specifications.

The mold trial serves as an essential quality control checkpoint in the injection molding process. It allows manufacturers to evaluate various factors, including material flow, mold fill, part ejection, and potential defects. Adjustments are typically made based on the results of the mold trial before full-scale production begins.

Why Are Mold Trials Important?

Mold trials are vital for several reasons, and they offer numerous benefits for manufacturers. Here are the primary reasons why mold trials are essential in the manufacturing process:

1. Ensuring Part Quality

The most important purpose of a mold trial is to ensure that the parts produced meet the required quality standards. During the trial, manufacturers can inspect parts for any issues like short shots, sink marks, warping, or surface defects. If any defects are observed, adjustments can be made to the mold design or process parameters to correct the issue before full-scale production.

2. Validating Mold Design and Functionality

A mold trial serves as a final validation step for the mold design. It ensures that the mold can function as intended and produce parts with the correct dimensions, surface finish, and material characteristics. If any issues arise during the trial, such as improper material flow or uneven filling, designers can make necessary modifications to the mold.

3. Optimizing Process Parameters

Mold trials help manufacturers fine-tune injection molding process parameters, including injection pressure, temperature, and cycle time. By adjusting these parameters during the trial, manufacturers can achieve optimal part quality while reducing material waste and production costs.

4. Reducing Production Costs

By identifying and addressing issues during the mold trial, manufacturers can prevent costly mistakes in full-scale production. Early detection of defects or inefficiencies helps reduce material waste, minimize downtime, and avoid costly rework or scrap during production.

5. Improving Production Efficiency

Conducting a mold trial also helps manufacturers optimize cycle times and production speed. By refining process parameters and making necessary mold adjustments, manufacturers can achieve faster, more efficient production once the mold is in full operation.

The Mold Trial Process

The mold trial process typically involves several key steps, from initial setup to final evaluation. Here’s an overview of how a mold trial is conducted:

1. Mold Setup

Before the mold trial begins, the mold must be properly set up in the injection molding machine. This includes ensuring that the mold is securely mounted, the proper material is loaded, and all necessary cooling, heating, and injection systems are correctly configured. The mold trial begins once the machine and mold are ready for operation.

2. First Shot

The first shot is the initial injection of material into the mold. This is typically done under controlled conditions to evaluate the mold’s performance. After the first shot, the part is removed, and visual inspections are performed to check for any obvious defects, such as incomplete fills, material streaks, or surface imperfections.

3. Part Evaluation

The part produced during the first shot is evaluated based on several factors:

- Dimensional accuracy: Is the part within the specified tolerances?

- Surface finish: Is the surface smooth, or are there defects like flashing or burn marks?

- Structural integrity: Are there any signs of weak points, such as sink marks, warping, or cracking?

4. Adjustments and Fine-Tuning

If defects are identified during the mold trial, the mold design or process parameters are adjusted to address the issues. Common adjustments include:

- Injection pressure: Changing the injection pressure can affect material flow and part quality.

- Cycle time: Modifying cycle time can help improve cooling rates and reduce warping.

- Mold temperature: Adjusting the temperature of the mold or material can improve material flow and part consistency.

5. Repetition and Optimization

After adjustments are made, the mold trial is repeated to test whether the changes improve part quality and consistency. Multiple shots may be required to optimize the process, and additional changes may be needed to achieve the desired results.

6. Final Approval

Once the mold trial produces parts that meet the quality requirements and specifications, the mold is approved for full-scale production. At this point, the mold is ready to be used in the manufacturing process for mass production.

Common Issues Detected During Mold Trials

While mold trials are essential for identifying issues, several common problems may arise during this phase:

1. Short Shots

A short shot occurs when the material does not fill the entire mold cavity, resulting in incomplete parts. This can be caused by low injection pressure, inadequate mold temperature, or improper material flow.

2. Warping

Warping happens when parts distort after cooling due to uneven cooling rates or inconsistent material flow. Mold temperature and cooling system adjustments can help resolve this issue.

3. Sink Marks

Sink marks are depressions that appear on the surface of a molded part when the material shrinks unevenly during cooling. This issue can be corrected by adjusting the injection speed, pressure, or cooling time.

4. Flashing

Flashing is the unwanted excess material that escapes from the mold cavity. This often occurs due to high injection pressure or misalignment in the mold components.

5. Surface Defects

Surface defects such as burn marks, streaks, or discoloration may appear due to incorrect injection temperature, material contamination, or inadequate cooling.

Benefits of Mold Trials

Conducting a mold trial offers several key benefits for manufacturers:

1.Early Detection of Issues: Mold trials help catch issues before full-scale production begins, reducing the risk of defects in finished parts.

2.Improved Part Quality: By refining the mold and process parameters, manufacturers can produce higher-quality parts that meet customer specifications.

3.Cost Savings: Detecting and addressing issues early helps reduce material waste, scrap, and rework, leading to cost savings in the long run.

4.Optimized Production: By fine-tuning the process during the mold trial, manufacturers can optimize cycle times, reduce downtime, and improve overall production efficiency.

Mold trials are an essential step in the injection molding process, allowing manufacturers to verify mold functionality, identify defects, and fine-tune process parameters before full-scale production. By conducting thorough mold trials, manufacturers can ensure that their molds produce high-quality parts, reduce the risk of defects, and optimize production efficiency. Whether you’re launching a new product or refining an existing design, mold trials are key to achieving success in injection molding.