In injection molding, the sprue is one of the most important components of the mold system. It serves as the primary channel through which molten plastic flows from the injection machine nozzle into the mold cavity. The design and proper use of the sprue are critical for ensuring a smooth, efficient molding process, as well as high-quality parts. Understanding the different types of sprues and how to use them can help manufacturers optimize material flow, reduce waste, and improve overall productivity.

This article will explore the role of the sprue in injection molding, its various types, and best practices for using and optimizing it.

What Is a Sprue in Injection Molding?

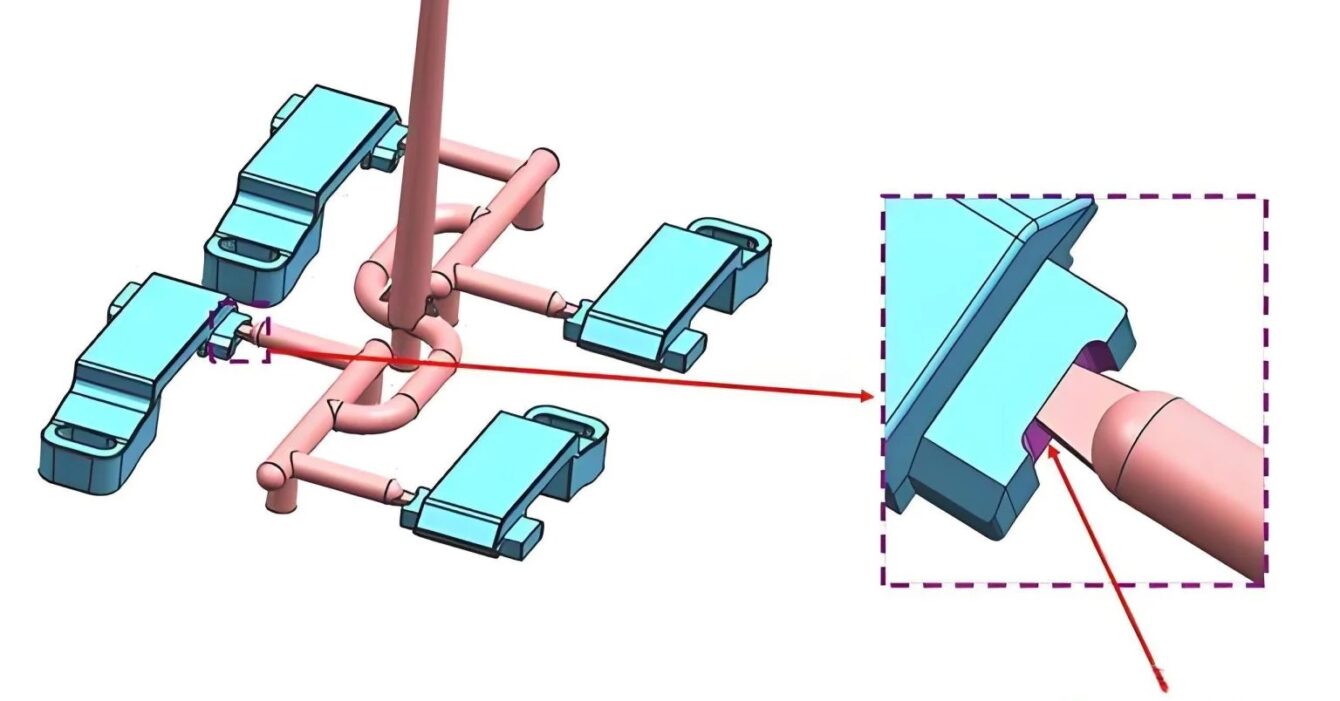

A sprue is the initial entry point for molten plastic in the injection molding process. It connects the injection machine’s nozzle to the runner system, which distributes the plastic into the individual mold cavities. The sprue is typically a vertical or angled passage, designed to efficiently guide the plastic into the mold cavity without causing defects in the molded part.

The key functions of a sprue are to:

- Deliver molten plastic: The sprue directs molten plastic from the injection machine’s nozzle into the mold cavity.

- Control flow rate: Properly designed sprues help regulate the flow of material into the cavity, which is critical for achieving uniform part quality.

- Minimize waste: A well-designed sprue minimizes excess plastic and waste material.

Types of Sprues in Injection Molding

There are several types of sprues used in injection molding, each suited to different molding applications. The most common types include:

1. Straight Sprue

- Description: The straight sprue is the most basic type of sprue. It is a direct, straight passage from the injection nozzle to the mold cavity or runner system.

- Applications: Used in simple molding applications where minimal material flow control is needed.

- Advantages: Simple design, easy to manufacture, and cost-effective.

- Disadvantages: Can result in uneven material distribution, especially in complex or multi-cavity molds.

2. Tapered Sprue

- Description: A tapered sprue gradually narrows as it moves from the injection nozzle to the mold cavity, which helps control the flow of molten material.

- Applications: Used when a more controlled flow is needed, particularly in applications where material pressure and flow need to be managed more precisely.

- Advantages: Helps to reduce material waste and minimizes the risk of overfilling.

- Disadvantages: Slightly more complex to design and manufacture than a straight sprue.

3. Heated Sprue

- Description: A heated sprue incorporates a heating element within the sprue system to prevent the plastic from cooling prematurely before it enters the mold cavity.

- Applications: Ideal for high-viscosity materials, such as thermosets or thick-walled parts, where maintaining material flow is critical.

- Advantages: Prevents material from solidifying and clogging the sprue, ensuring smooth material flow and reducing the chances of defects.

- Disadvantages: Increased energy consumption and additional cost for heating elements.

4. Hot Runner Sprue

- Description: The hot runner sprue is part of a hot runner system, which keeps the material inside the sprue channel heated during the molding process. This type of sprue does not require cooling after the part is formed.

- Applications: Used in high-volume production where material waste and cooling time need to be minimized. Commonly used for parts requiring multiple cavities and high-precision molding.

- Advantages: Reduces material waste by maintaining molten plastic within the system and eliminates the need for sprue removal after molding.

- Disadvantages: Expensive initial setup due to the complexity of the hot runner system and additional maintenance costs.

5. Cold Runner Sprue

- Description: A cold runner sprue is part of a cold runner system, where the plastic cools down as it moves through the runner and into the cavity. It is generally used in molds where the sprue will be discarded after each cycle.

- Applications: Ideal for low-to-medium volume production where material savings are not as critical.

- Advantages: Simpler to design and maintain than hot runner systems.

- Disadvantages: Higher material waste since the sprue is ejected after each molding cycle.

How to Use a Sprue in Injection Molding

To ensure optimal performance of the sprue in injection molding, it’s essential to consider several factors when designing and using the sprue system. Here are key considerations for effective sprue use:

1. Proper Size and Design

- Sprue Size: The size of the sprue should be designed to accommodate the required flow of material while avoiding unnecessary pressure drop. A sprue that is too narrow can restrict the material flow, leading to defects like incomplete fills or short shots.

- Sprue Design: The sprue should be designed to ensure smooth material flow and minimal resistance. Using a tapered sprue or heated sprue can help achieve more controlled flow and avoid issues with material solidification.

2. Minimizing Waste

- Sprue Removal: In cold runner systems, the sprue is often removed and discarded after each cycle. Minimizing the size of the sprue can help reduce material waste and lower production costs.

- Hot Runner Systems: In hot runner systems, the sprue material is kept molten, eliminating waste and improving efficiency. This system is ideal for large-volume production where material conservation is important.

3. Optimizing Flow

- The design of the sprue should ensure that the flow of molten material is uniform and consistent, preventing issues like air traps or inconsistent filling. To optimize the flow, the sprue should be placed at the best entry point for the mold and positioned to direct the material evenly across the mold cavity.

4. Avoiding Short Shots and Flash

- Short Shots: A short shot occurs when the sprue is too small or the flow rate is too low, causing incomplete parts. To avoid this, ensure that the sprue and runner system are sized correctly and that the injection pressure is sufficient to fill the mold completely.

- Flash: Flash occurs when excess material escapes from the mold cavity due to excessive pressure or poorly designed sprues. Proper sprue design and control of injection speed and pressure can minimize flash.

Sprue Design Best Practices

To get the best results from your sprue design, consider the following best practices:

- Optimize the Runner System: Ensure the runner system is well-balanced, with equal flow to all cavities. This minimizes the risk of uneven part filling and material waste.

- Use Efficient Sprue Placement: Place the sprue at the most optimal point on the mold to minimize material travel distance and ensure consistent flow to all cavities.

- Select the Right Sprue Type: Choose between hot runner and cold runner sprues based on your production volume and material characteristics. Hot runner sprues are ideal for high-volume runs, while cold runner sprues are better suited for low-to-medium volume production.

- Consider Cooling Requirements: Design the sprue to allow for adequate cooling time and prevent premature material solidification, especially when using high-viscosity materials or complex part designs.