When it comes to injection molding, one of the most critical decisions manufacturers face is choosing between a single cavity mold and a multi cavity mold. Both mold types have their unique advantages, and understanding the differences between them is essential to optimize production efficiency, reduce costs, and ensure product quality. This guide will provide a detailed comparison of single cavity molds versus multi cavity molds, examining their pros and cons, ideal applications, and how to select the right mold for your production needs.

What Is a Single Cavity Mold?

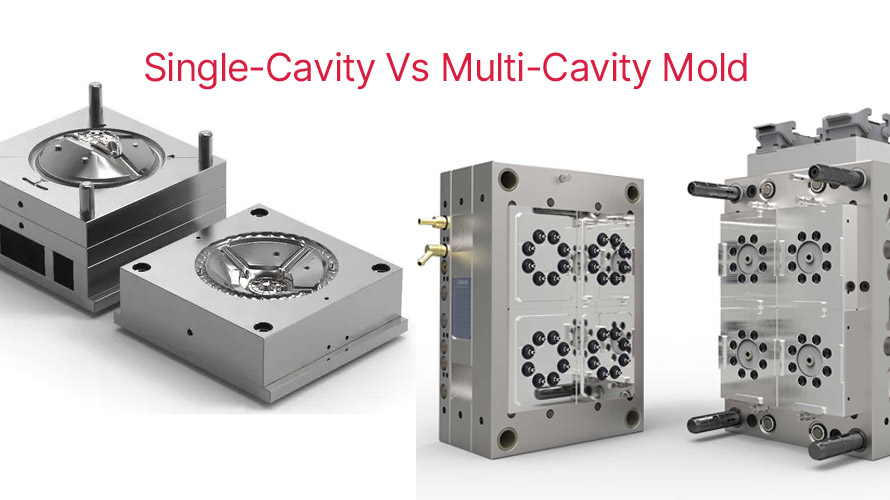

A single cavity mold is a type of injection mold that has only one cavity for producing a single part per injection cycle. It is the simplest form of mold and is commonly used for low-volume production runs or when only one part is needed at a time. The design of a single cavity mold is straightforward, with one set of core and cavity inserts that form the desired shape of the molded part.

Advantages of Single Cavity Molds

1.Simplicity: The design of a single cavity mold is less complex compared to a multi cavity mold, making it easier and faster to manufacture.

2.Cost-Effective for Low Volume: Because the mold has fewer components and is simpler to design, it is less expensive for low-volume production runs.

3.Faster Modifications: Modifying or repairing a single cavity mold is often quicker and more affordable due to its simpler design.

4.Flexibility: Ideal for parts that do not require multiple copies at once, or for prototyping, where part designs may change frequently.

Disadvantages of Single Cavity Molds

1.Lower Production Efficiency: Only one part is produced per cycle, which can lead to longer cycle times and higher labor costs for large quantities of parts.

2.Higher Per-Unit Cost: For larger production runs, the cost per part is higher when using a single cavity mold compared to a multi cavity mold.

What Is a Multi Cavity Mold?

A multi cavity mold is designed to produce multiple parts in a single injection cycle. Unlike a single cavity mold, a multi cavity mold includes multiple cavities, each forming an identical part. These molds are ideal for high-volume production runs, where multiple identical parts need to be produced simultaneously.

Advantages of Multi Cavity Molds

1.Increased Production Efficiency: Multi cavity molds allow multiple parts to be produced in one cycle, reducing overall cycle time and increasing production throughput.

2.Lower Cost Per Part: With multiple parts produced in a single cycle, the cost per unit is significantly lower than that of single cavity molds, making it ideal for large-scale production.

3.Consistent Quality: Since all cavities in a multi cavity mold are filled at the same time with the same amount of material, part consistency is often higher, reducing variations in size or shape.

4.Better Material Utilization: With multiple parts being produced at once, multi cavity molds tend to have better material efficiency, as less material is wasted in the molding process.

Disadvantages of Multi Cavity Molds

1.Higher Initial Cost: Multi cavity molds are more complex to design and manufacture, which leads to higher initial costs.

2.Longer Design and Lead Time: The design and setup time for a multi cavity mold is typically longer than for a single cavity mold, making it less suitable for quick-turnaround projects.

3.Complex Maintenance: Maintenance and repairs can be more challenging and expensive due to the greater number of cavities and moving parts involved in the mold.

4.Higher Risk of Mold Failure: If a defect occurs in one cavity, it can affect the quality of all the parts being produced, leading to a higher risk of rejects.

Single Cavity Mold vs Multi Cavity Mold: Key Differences

To better understand the key differences between a single cavity mold and a multi cavity mold, the table below compares these two types across various parameters:

| Feature | Single Cavity Mold | Multi Cavity Mold |

|---|---|---|

| Production Volume | Ideal for low-to-medium volume production | Best for high-volume production |

| Cost | Lower initial cost | Higher initial cost due to complexity |

| Cycle Time | Longer cycle times | Shorter cycle times (multiple parts per cycle) |

| Complexity | Simple design and setup | More complex design with multiple cavities |

| Per-Unit Cost | Higher cost per part | Lower cost per part |

| Maintenance | Easier and less expensive maintenance | More complex and expensive maintenance |

| Product Consistency | May vary in quality between parts | Higher consistency in part quality |

| Flexibility | More flexible for prototype or custom parts | Less flexible; suited for high-volume, standardized parts |

| Tooling and Modification | Easier to modify and adjust | Modifications can be costly and time-consuming |

When to Use a Single Cavity Mold?

A single cavity mold is best suited for the following scenarios:

1.Low Volume Production: If you need to produce a small quantity of parts or test prototypes, a single cavity mold is an ideal choice due to its lower initial investment and simpler design.

2.Custom or Complex Parts: When the parts are unique or have intricate features, a single cavity mold allows for more design flexibility.

3.Short Production Runs: When fast setup times and flexibility are critical, single cavity molds are often the preferred choice.

When to Use a Multi Cavity Mold?

A multi cavity mold is best suited for:

1.High Volume Production: For large production runs, multi cavity molds are more efficient, as they allow multiple parts to be produced in one cycle.

2.Cost-Efficiency: When aiming for lower per-unit production costs, a multi cavity mold is more cost-effective for large orders.

3.Consistent Quality: If product consistency and high-quality standards are essential, multi cavity molds provide uniform results across all parts produced.

4.Mature Product Designs: Once the product design is finalized and there are no major changes expected, a multi cavity mold is ideal for maximizing production efficiency.

How to Choose the Right Mold for Your Production

Selecting the right mold for your production depends on several factors, including part complexity, production volume, cost considerations, and turnaround time. Here are some guidelines:

1.Consider Production Volume: If you need to produce a large number of parts quickly and efficiently, multi cavity molds are the best choice. For lower volumes, a single cavity mold may be sufficient.

2.Evaluate the Product’s Complexity: For parts with intricate or custom designs, a single cavity mold may offer more flexibility. For standardized parts with simple geometry, multi cavity molds will be more efficient.

3.Factor in Cost: While multi cavity molds offer lower per-unit costs for high-volume production, they come with a higher initial investment. For smaller production runs, single cavity molds might be more economical.

4.Maintenance and Modifications: If you anticipate frequent modifications to the design, a single cavity mold is easier to alter. For large-scale production, however, multi cavity molds offer greater efficiency once the design is set.

Both single cavity molds and multi cavity molds offer distinct advantages and challenges, depending on your production needs. Single cavity molds are ideal for low-volume production, prototyping, and parts with complex designs, while multi cavity molds are suited for high-volume runs that require cost efficiency and consistent quality. By understanding the differences between these two types of molds and assessing your specific production requirements, you can make an informed decision that optimizes both cost and efficiency in your injection molding process.