In the mold-making business for over a decade, I’ve seen too many clients fall into the same traps—wrong steel selection leading to rapid wear during mass production, or molds cracking after just a few thousand cycles. Today, let’s cut through the technical jargon and talk practical insights: How to choose the right injection mold core steel for your specific needs? What’s the real-world lifespan of different steels? What pitfalls should you avoid? These are the questions I’ll answer based on years of hands-on experience, sharing lessons learned from the shop floor to help you make smarter decisions.

I. Why Do Injection Mold Cores Fail? Understanding the Root Causes

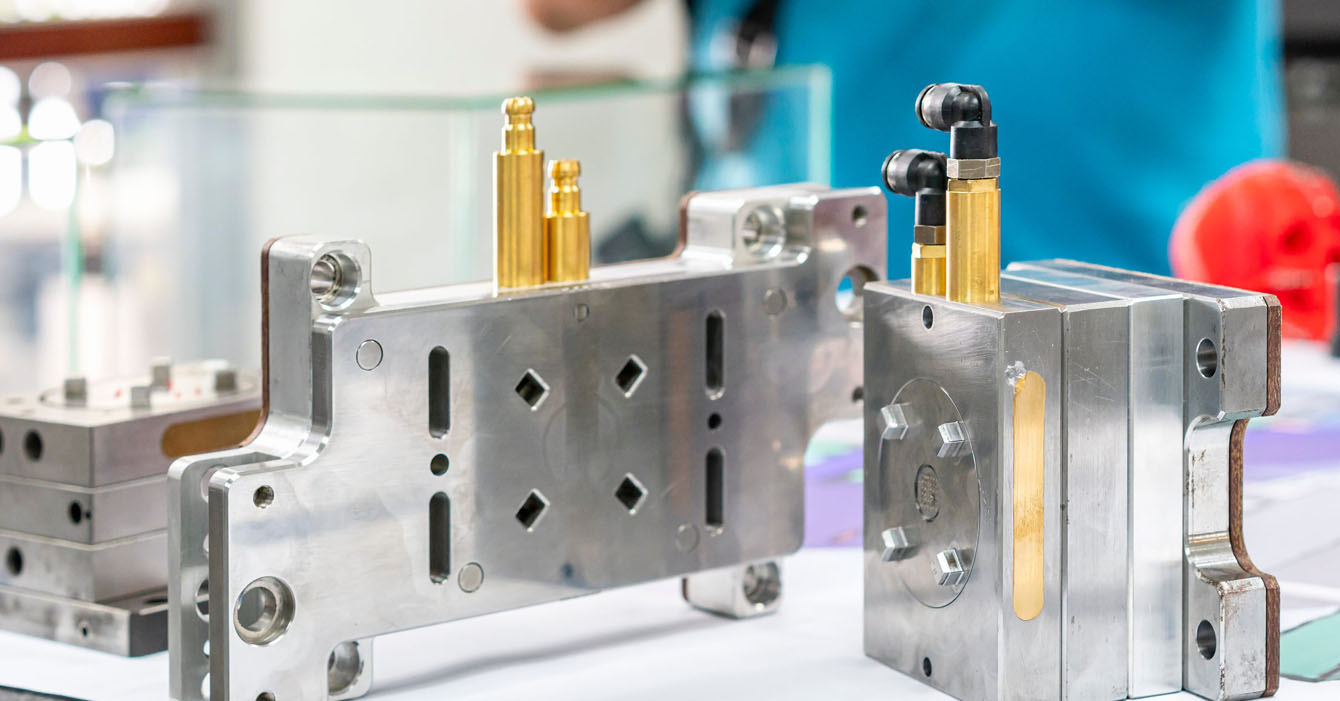

The mold core is the “heart” of the injection mold—the part that directly contacts the molten plastic. Its lifespan is primarily challenged by three factors:

- Abrasion from Molten PlasticPlastics with fillers like glass fibers (e.g., PA66 + 30% GF) act like tiny blades, grinding against the core’s surface. Softer steels wear down quickly, causing dimensional drift in your parts.

- Corrosive AdditivesPlastics like PVC release hydrochloric acid (HCl) as they decompose. Ordinary steels corrode, leading to pitting and surface defects on your parts.

- High-Volume Production StressMass-production molds cycle thousands of times daily. Repeated heating and cooling create thermal fatigue, causing micro-cracks that eventually lead to catastrophic failure.

Choosing the right steel is about balancing hardness (wear resistance), corrosion resistance, and toughness (crack resistance) based on your specific plastic type and production volume.

II. Common Injection Mold Core Steels: A Practical Breakdown

Let’s categorize steels by use case—trial runs vs. high-volume production—and share real-world insights from my shop.

1. P20: The “Starter Steel” for Prototypes

Best for: Simple plastics like PP, PE, and PS (e.g., plastic containers, housings). Ideal for prototyping or low-volume runs (<50,000 cycles).

Why it works: Pre-hardened (no additional heat treatment needed), easy to machine, and cost-effective.

Lifespan: 30,000–100,000 cycles. But expect wear over time—glass-filled plastics or high-volume use will shorten this dramatically.

Watch out for: Not suitable for long-term production. If your client suddenly scales up to 500,000 parts, you’ll need to upgrade.

Real-world example: A client made PP storage boxes with P20. Prototyping was fast and cheap, but after 80,000 cycles, the mold showed 0.1mm wear, causing part misfits. Switching to H13 fixed the issue—but at a higher cost.

2. NAK80: The “Mirror Finish” Choice for High-Gloss Parts

Best for: ABS, PC, and other transparent or high-gloss plastics (e.g., phone cases, cosmetic caps).

Why it works: Pre-hardened, polished to a mirror finish (Ra ≤ 0.1μm), and corrosion-resistant. No post-mold coating needed.

Lifespan: 150,000–500,000 cycles. Best for non-glass-filled plastics—glass fibers accelerate wear.

Watch out for: Avoid complex, thin-walled designs. Its toughness is lower than H13, so sharp corners may chip.

Case study: A cosmetics brand needed flawless, mirror-like caps. NAK80 delivered 300,000 cycles with zero surface defects, keeping their rejection rate under 1%.

3. H13: The “Workhorse” for Engineering Plastics

Best for: Glass-filled nylons (PA66 + GF), PBT, and other tough engineering plastics. High-volume production (500,000+ cycles).

Why it works: Hardened to HRC 48–52, it resists glass fiber abrasion and thermal fatigue. The industry standard for durability.

Lifespan: 500,000–1,500,000 cycles. We’ve seen H13 molds last 850,000 cycles for automotive connectors.

Watch out for: Requires proper heat treatment (most suppliers handle this, but double-check hardness specs).

Example: A client switched from P20 to H13 for PA66 + 40% GF connectors. The H13 mold ran 850,000 cycles with only minor wear—polishing restored performance.

4. S136: The “Anti-Corrosion” Pick for PVC and Flame-Retardant Plastics

Best for: PVC, CPVC, and flame-retardant ABS (which release corrosive acids). Medical or food-grade molds.

Why it works: Exceptional corrosion resistance (no rust, no pitting) and excellent polishability.

Lifespan: 300,000–1,000,000 cycles. Outlasts ordinary steels in harsh environments.

Watch out for: More expensive than P20 (2–3x the cost), but worth it for corrosive plastics.

Client story: A PVC pipe manufacturer struggled with rust spots after 30,000 cycles. Switching to S136 eliminated corrosion and extended mold life to 300,000 cycles.

III. Injection Mold Steel Lifespan Comparison: Quick Reference

| Steel Type | Best For | Lifespan (Cycles) | Key Advantage | Trade-off |

|---|---|---|---|---|

| P20 | PP/PE/PS (simple plastics) | 30K–100K | Cheap, fast machining | Wears quickly under load |

| NAK80 | ABS/PC (high-gloss) | 150K–500K | Mirror finish, corrosion-resistant | Less tough for complex designs |

| H13 | PA66+GF (engineering plastics) | 500K–1.5M | Abrasion-resistant, durable | Higher cost |

| S136 | PVC/flame-retardant plastics | 300K–1M | No corrosion, polished finish | Expensive |

IV. Pro Tips from the Shop Floor

- Prototyping? Stick with P20—it’s fast and affordable.

- High-gloss parts? NAK80 saves post-processing costs.

- Glass-filled plastics? H13 is non-negotiable for longevity.

- Corrosive plastics? S136 avoids costly mold damage.

Remember: The best steel isn’t always the most expensive—it’s the one that matches your production needs. Need help selecting? Hit me up, and we’ll figure it out together.(Next up: Die-casting mold steels—where the challenges get even tougher!)

Bonus: Want to see actual polish comparisons or wear-test photos? Drop a comment, and I’ll share our workshop examples.