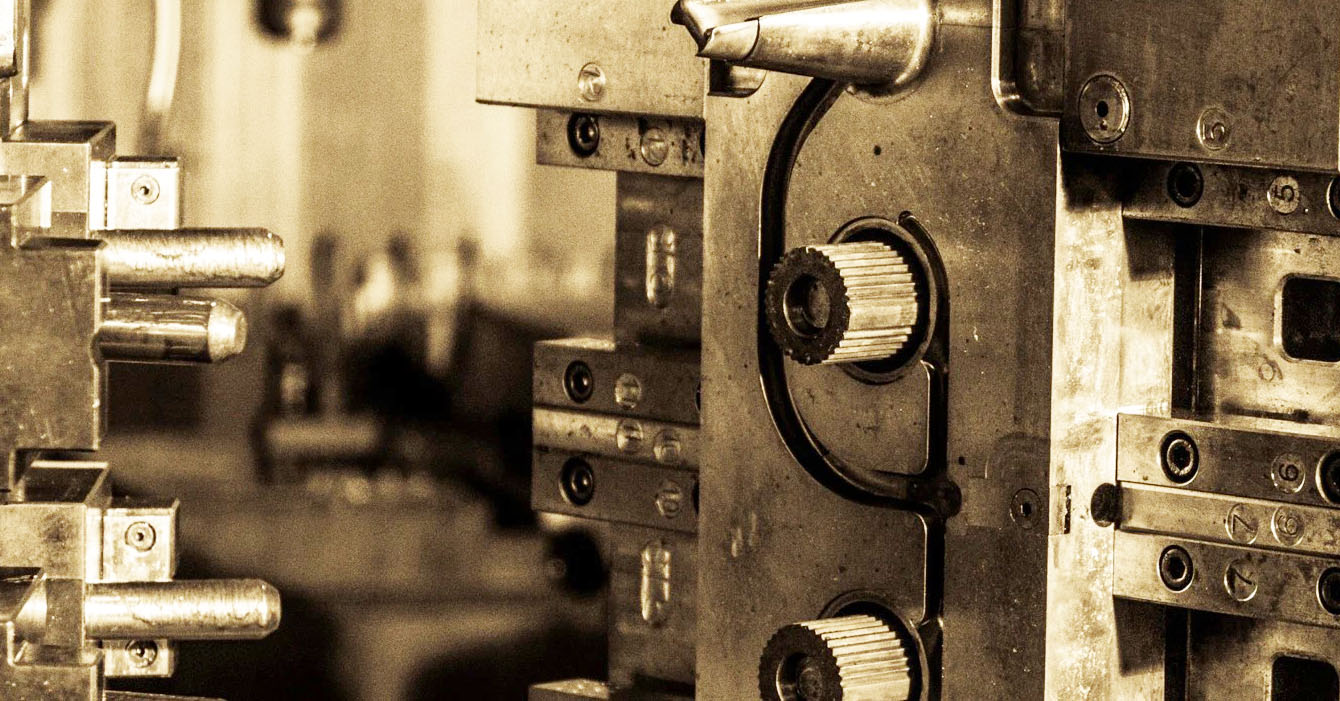

If you’ve worked with die-casting, you’ve heard these complaints: “The mold keeps cracking!” “We’re only getting 20,000 shots before repairs!”I’ve seen it all—clients cutting corners on steel to save costs, only to watch molds fail prematurely. Today, let’s break down how to select die-casting mold steels for aluminum (ADC12), zinc (ZA-8), and magnesium alloys, and more importantly, how to make them last through high-volume production.

I. Why Die-Casting Molds Fail (And How Steel Helps)

Die-casting molds face brutal conditions:

1.Extreme Heat: Molten aluminum hits 680–720°C (1,250–1,330°F). The mold must withstand this without softening.

2.High Pressure: Metal injection pressures reach 50–150 MPa (7,000–22,000 PSI)—enough to deform weak steel.

3.Thermal Shock: Rapid heating (metal pour) and cooling (mold opening) create cracks over time (“thermal fatigue”).

4.Metal Impact: Thin-walled parts (e.g., 0.5mm phone cases) expose molds to high-velocity metal flow, which can erode the surface.

Your mold steel’s job? Resist abrasion (from metal particles), corrosion (from alloy reactions), and thermal fatigue (from repeated heating/cooling).

II. Common Die-Casting Mold Steels: By Production Volume

Here’s how to match steel to your needs, with lessons from real projects.

1. H13: The Industry Standard (But Not Always the Best)

Best for: ADC12 aluminum and ZA-8 zinc in medium volumes (e.g., 50,000–200,000 shots).

Why it works: Hardened to HRC 48–52, it balances hardness (resists wear) and toughness (handles thermal stress).

Lifespan: 30,000–100,000 shots (standard) to 100,000–200,000 (with optimized cooling).

Watch out for: Not ideal for ultra-high-volume or ultra-thin parts. Thermal fatigue cracks appear after prolonged use.

Case study: A client making ADC12 car brackets ran an H13 mold for 80,000 shots before fine cracks appeared. Switching to 8407 extended life to 180,000 shots.

2. 8407: The Longevity Champion for High Volume

Best for: High-volume aluminum parts (e.g., 1M+ annual production, like car grilles or AC housings).

Why it works: An upgraded H13 with better thermal fatigue resistance (up to 50% longer life) and minimal distortion during heat treatment.

Lifespan: 80,000–200,000 shots (standard) to 300,000+ (with great cooling design).

Watch out for: 10–20% more expensive than H13, but pays off in reduced downtime.

Example: A car grille mold using 8407 lasted 220,000 shots—double an H13 mold’s typical life. The client saved $40,000/year in mold replacements.

3. SKD61: Precision for Thin Walls and Complex Geometry

Best for: Precision parts (e.g., gears, turbines) or thin walls (<0.5mm).

Why it works: Similar to H13 but with purer composition—fewer impurities mean fewer sudden cracks.

Lifespan: 50,000–150,000 shots. Ideal when part tolerances are tight (e.g., 0.01mm gaps).

Watch out for: Similar cost to H13; only worth it if precision is critical.

Client win: A micro-gear mold switched to SKD61 and eliminated crack-related defects, maintaining 99.9% yield over 120,000 shots.

4. DAC: The “Tough Guy” for Ultra-Thin Parts

Best for: Super-thin aluminum (0.3–0.5mm, e.g., phone SIM trays, drone frames).

Why it works: Harder (HRC 50–52) and more resistant to metal impact erosion.

Lifespan: 50,000–120,000 shots. Protects against thin-wall fill issues.

Watch out for: Slightly lower toughness than H13—design sharp corners carefully.

Real-world fix: A phone case mold using H13 kept cracking at thin edges. DAC solved the problem, with zero fill defects and 100,000+ shots.

5. INCONEL 625 (Nickel Alloy): For Exotic Alloys (Rarely Used)

Best for: Titanium or super-alloy die-casting (almost never for aluminum/zinc).

Why it works: Handles extreme heat (1,000°C+) and resists metal corrosion.

Lifespan: 50,000–100,000 shots. Overkill for standard dies—costs 10x more than H13.

Fun fact: We’ve used INCONEL 625 once for a titanium prototype. It worked, but the client switched to aluminum for cost reasons.

III. Die-Casting Mold Steel Lifespan Comparison

| Steel Type | Best For | Lifespan (Shots) | Key Advantage | Trade-off |

|---|---|---|---|---|

| H13 | ADC12/Zn (medium volume) | 30K–100K (standard) 100K–200K (optimized) | Balanced cost/durability | Thermal fatigue over time |

| 8407 | High-volume aluminum | 80K–200K (standard) 300K+ (great cooling) | Longest-lasting option | 10–20% pricier than H13 |

| SKD61 | Precision/thin walls | 50K–150K | Fewer sudden cracks | Similar cost to H13 |

| DAC | Ultra-thin parts | 50K–120K | Resists metal erosion | Slightly less tough |

| INCONEL 625 | Exotic alloys (rare) | 50K–100K | Extreme heat resistance | Extremely expensive |

IV. Pro Tips for Die-Casting Success

- Prototyping? H13 is fine for initial trials.

- Mass production? 8407 saves money long-term.

- Thin walls? DAC prevents fill defects.

- Precision parts? SKD61 minimizes cracks.

- Exotic metals? Only use INCONEL 625 if absolutely necessary.

Key takeaway: The right steel + smart cooling design = a mold that lasts. Need help picking? Ask me—we’ll find your best fit.(Next: How cooling channels work with your steel choice—the hidden factor that doubles mold life!)

PS: Want to see H13 vs. 8407 crack photos or thermal fatigue test data? Comment below, and I’ll share our shop’s findings.