Why Quotation Transparency Matters

When buying a custom injection mold, the quotation is more than just a number — it’s a map of where your money goes. Many buyers focus only on the total price, missing crucial details that affect quality, lead time, and long-term costs. Understanding the mold cost breakdown helps you:

- Compare suppliers on a like-for-like basis

- Identify unnecessary or inflated charges

- Make informed trade-offs between cost, lead time, and durability

- Avoid “low price, high risk” traps

Let’s decode the typical injection mold quotation into its core components.

1. Material Costs – The Foundation of Mold Longevity

Material cost is usually 30–50% of the total mold price for standard molds, higher for complex or high-performance steels.Main factors:

- Steel grade: P20 (pre-hardened, economical) vs. H13 (through-hardened, high wear resistance) vs. S136 (stainless, corrosion resistant)

- Size & weight: Larger blocks = more material + heavier machining cost

- Brand/source: Imported premium steel (e.g., ASSAB, Daido) costs more than domestic equivalents but may offer tighter tolerances and proven life expectancy

Tip: Don’t choose steel based solely on name — match it to your injection molding material and production volume (see our steel selection guide).

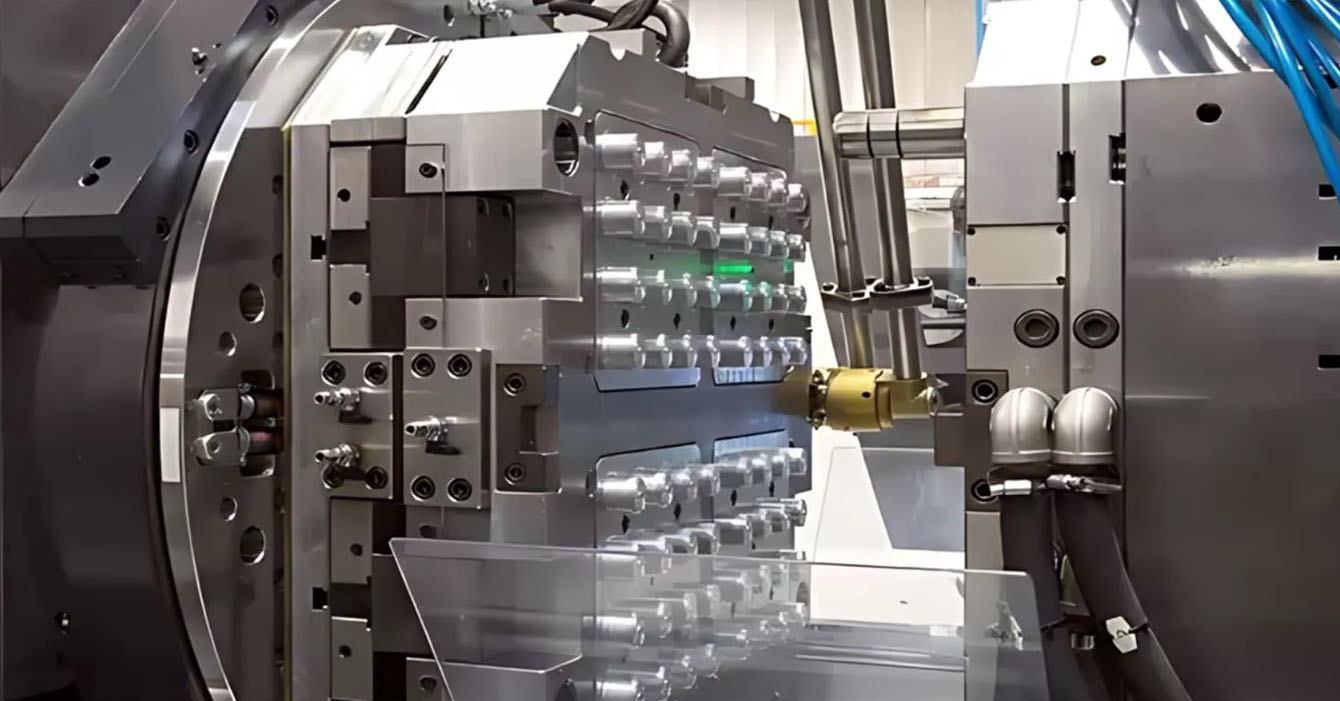

2. Machining & Fabrication Costs – Where Precision Adds Up

Machining typically accounts for 25–40% of the quote. This includes:

- CNC milling (rough & finish) – complexity, number of setups, and tolerance requirements drive cost

- EDM (Electrical Discharge Machining) – for fine details, deep ribs, or hard steel areas

- Wire-cut EDM – for precision slots and inserts

- Grinding & polishing – surface finish requirements (e.g., mirror finish for transparent parts) significantly increase hours

- Heat treatment – hardening, tempering, nitriding (essential for wear resistance, adds time & cost)

Hidden cost drivers:

- Tight tolerances (±0.005 mm vs. ±0.02 mm) multiply setup and inspection time

- Multiple electrodes or complex 3D profiling increase EDM hours

- Special textures or laser engraving require additional processes

3. Design & Engineering Costs – The Brain Behind the Mold

Design cost is usually 5–15% of the total, but it’s critical to final product success.Includes:

- DFM analysis – evaluating part geometry for manufacturability, suggesting changes to reduce mold complexity

- 3D modeling & mold flow simulation – predicts filling, cooling, and potential defects before machining starts

- Iterative revisions – design changes after signing contract may incur extra fees unless capped in the agreement

Tip: Reputable suppliers include basic DFM in the quote. If they skip it, ask why — skipping DFM often means costly changes later in mold build.

4. Assembly & Testing Costs – From Blocks to Working Mold

Assembly & tryout (T0, T1, T2 samples) typically represent 5–10% of the quote.

- Assembly: Fitting core/cavity, ejector system, sliders, hot runner components

- First article inspection (FAI): Verifying dimensions, surface finish, and function

- Trial runs: Adjusting process parameters to achieve acceptable parts

- Revisions: Fixing issues found during testing (e.g., mismatch, flash, short shot)

Note: Some suppliers quote “mold only” and charge separately for sampling — clarify if sampling is included and how many shots are allowed.

5. Hidden & Ancillary Costs – The Fine Print

These can turn a seemingly competitive quote into a budget buster:

- Tooling electrodes & consumables: Often itemized separately for EDM

- Special coatings: Nitriding, TiN, DLC coatings improve life but add cost

- Hot runner system: Either included or quoted separately (brand, valve gate vs. open nozzle matters)

- Surface texture: SPI finishes A-1 to D-3 impact polishing time

- Packaging & transport: Domestic vs. international shipping, customs duties

- After-sales service: Warranty period, included maintenance visits, spare parts cost

Negotiation tip: Request an itemized quotation with assumptions clearly stated (steel grade, surface finish, number of cavities, included samples, delivery terms).

Sample Cost Breakdown Table (Illustrative)

| Item | % of Total Quote | Notes |

|---|---|---|

| Steel material | 35% | H13 block, imported |

| Machining (CNC/EDM/Grind) | 30% | Includes heat treatment |

| Design & Simulation | 10% | DFM + flow analysis |

| Assembly & Tryout | 10% | 5 shots included |

| Hot Runner System | 8% | Valve gate, brand X |

| Surface Texture & Coating | 4% | SPI-A2, nitrided |

| Others (electrodes, transport) | 3% | FOB port |

How to Evaluate & Negotiate Quotes

1.Compare item by item, not just total price.

2.Check assumptions: Same steel grade, cavity number, surface finish, included samples.

3.Assess supplier capability: Equipment list, certifications (ISO 9001, IATF 16949), past projects.

4.Clarify payment terms: Typical is 30% deposit, 70% before shipment.

5.Include revision caps: Limit extra design/machining charges if changes are required after PO.

6.Evaluate total cost of ownership: A cheaper mold that lasts 100k shots is better than an ultra-cheap one needing major repair at 30k shots.

Knowledge Turns Quotes Into Power

Understanding your injection mold quotation puts you in control. With transparent cost breakdowns, you can confidently choose a supplier that aligns with your custom injection molding quality and budget goals — and avoid surprises after the purchase.Need help reviewing a supplier’s quote? Send it over (remove confidential info), and our engineers will give you a free line-by-line assessment.(P.S. Want an editable Excel cost-breakdown template? Comment “QUOTE TEMPLATE” and we’ll email it to you.)