In the injection molding process, the design of the mold plays a critical role in the production efficiency, cost-effectiveness, and part quality. Among the various mold configurations, the two-plate mold and three-plate mold are the most widely used, each with its own set of advantages and limitations. Understanding the differences between these two types of molds is crucial for manufacturers when choosing the right mold for their production needs.

This article will compare the two-plate mold and three-plate mold, highlighting their key features, advantages, disadvantages, and best use cases to help you make an informed decision for your injection molding operations.

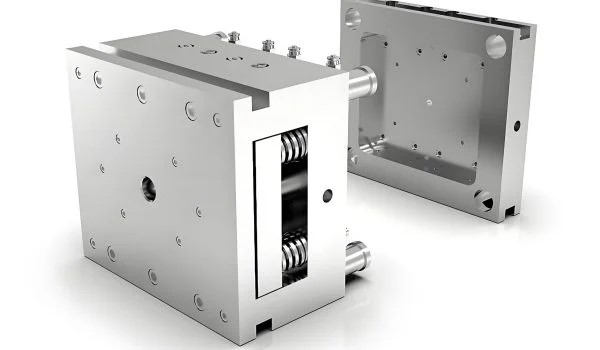

What Is a Two-Plate Mold?

A two-plate mold is the most basic and widely used mold configuration in injection molding. It consists of two primary parts:

- A Plate (Cavity side): This side contains the mold cavity where the plastic material will be injected and molded.

- B Plate (Core side): This side contains the core, which shapes the molded part after the plastic has cooled.

When the mold is closed, these two plates come together to form the cavity. Once the part is molded, the plates separate to eject the part, and the cycle starts over.

Key Features of Two-Plate Mold

- Simple design with fewer components.

- Cost-effective for low-to-medium volume production.

- Ideal for simple parts with a single cavity.

- Easier and faster to produce than a three-plate mold.

Advantages of Two-Plate Mold

- Lower Cost: Due to its simpler design and fewer components, a two-plate mold is generally more affordable than a three-plate mold.

- Shorter Lead Time: The simpler design allows for faster mold production, making it ideal for shorter lead times.

- Ease of Maintenance: With fewer moving parts, maintenance and repairs are typically less complex and less costly.

Disadvantages of Two-Plate Mold

- Limited Design Flexibility: A two-plate mold is typically limited to simpler parts and applications. More complex parts with multiple cavities or intricate gating systems may require a more advanced mold design.

- Manual Runner Removal: In some cases, the runner system is manually removed from the molded parts, which can add labor time and cost.

What Is a Three-Plate Mold?

A three-plate mold includes three plates instead of two, consisting of:

1.A Plate (Cavity side): Similar to the two-plate mold, this plate contains the cavity where the part is molded.

2.B Plate (Core side): This plate contains the core, which defines the interior shape of the molded part.

3.C Plate: The C plate is an additional plate placed between the A and B plates. This plate helps separate the runner system from the molded part during ejection.

The C plate introduces a third level of separation between the part and the runner system, making it ideal for parts that require additional gating or a more complex injection system.

Key Features of Three-Plate Mold

- More complex design with three separate plates.

- Suitable for more complex or high-volume production runs.

- Allows automatic separation of runners from parts during ejection.

Advantages of Three-Plate Mold

- Better for Complex Parts: The three-plate design is ideal for parts with intricate geometries, multiple gates, or multi-cavity molds.

- Automatic Runner Removal: The C plate allows for automatic removal of runners, which can reduce labor costs and improve overall production efficiency.

- Greater Design Flexibility: Three-plate molds allow for greater flexibility in design, enabling the production of more complex parts that would be difficult or impossible to mold using a two-plate mold.

Disadvantages of Three-Plate Mold

- Higher Cost: The complexity of the design, along with the additional components, makes three-plate molds significantly more expensive than two-plate molds.

- Longer Lead Time: Due to the added complexity, the design and manufacturing process for a three-plate mold typically takes longer.

- Increased Maintenance: With more moving parts, three-plate molds generally require more frequent maintenance and repair, which can add to operational costs.

Key Differences Between Two-Plate and Three-Plate Molds

| Feature | Two-Plate Mold | Three-Plate Mold |

|---|---|---|

| Design Complexity | Simple, two plates | Complex, three plates |

| Cost | More affordable | More expensive due to added complexity |

| Lead Time | Shorter production time | Longer production time due to complexity |

| Part Complexity | Ideal for simple parts | Suitable for complex parts and multi-cavity molds |

| Runner System | Manual removal of runners | Automatic separation of runners |

| Maintenance | Easier to maintain | More frequent and expensive maintenance |

| Production Volume | Suitable for low-to-medium volumes | Suitable for high-volume production runs |

| Ejection Process | Single ejection system | Multiple ejection systems due to C plate |

When to Use a Two-Plate Mold?

A two-plate mold is ideal when:

- Producing simple, single-cavity parts.

- You need a more cost-effective solution for low- to medium-volume production.

- Fast turnaround time is required.

- The design is relatively straightforward without complex gating or runner systems.

When to Use a Three-Plate Mold?

A three-plate mold is more suitable when:

- The part design is complex and requires multiple gates or cavities.

- You are producing parts with intricate geometries that require precise molding.

- Higher volume production is needed, and efficiency in runner removal is critical.

- The project justifies the higher initial cost due to the increased automation and reduced manual labor.

Choosing between a two-plate mold and a three-plate mold ultimately depends on the complexity of the parts being produced, the volume of production, and the budget available for mold manufacturing. Two-plate molds offer a simpler, cost-effective solution for less intricate designs, while three-plate molds provide the flexibility and automation needed for more complex, high-volume applications. Understanding the key differences between the two will help manufacturers optimize production processes and select the best mold configuration for their needs.