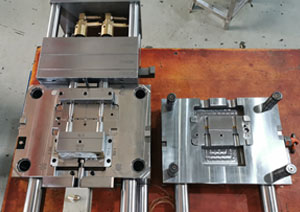

Threaded Waterway Mold

The Threaded Waterway Mold is designed for the production of PC (Polycarbonate) plastic parts with a single cavity (12) and an injection system utilizing edge gating. The product weighs 1.8g, with a shrinkage rate of 6.5‰. The mold operates on a 120T injection molding machine and utilizes high-quality materials such as H13 for the core and NAK80 for inserts, ensuring durability and precision.

Specification:

| Project name | Threaded Waterway Mold | Part Material | PC (Polycarbonate) |

| Part Weight | 1.8g | Shrinkage Rate | 6.5‰ |

| Injection Machine | 120T | Injection System | edge gate injection |

| Cavity | 2 | Mold Base Standard | DME Standard |

| Core Material | Imported Beryllium Copper C17200 (Hardness HRC 36-42) | Mold Dimensions | 200 x 200 x 246mm |

| Mold Weight | 370kg | Manufacturing Lead Time | 4weeks |

| Design Lead Time | 3days |

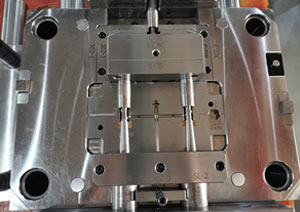

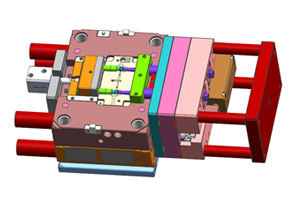

Mold Desgin

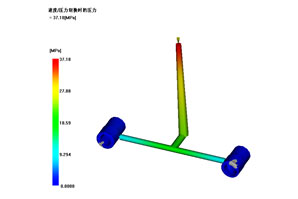

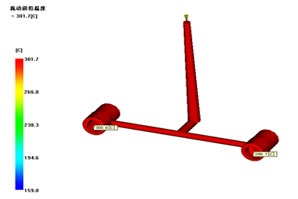

Mold Flow Analysis: The analysis showed that the molding cycle required 30 seconds, but the customer requested 22 seconds. |

Design: The original design did not include cooling channels for the threaded core. |

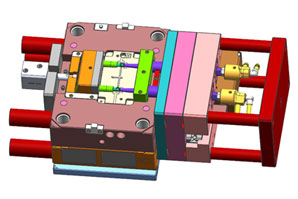

Cycle Reduction Solution: We incorporated cooling channels into the threaded core design and used chilled water cooling. |

Design Modification: The design was updated to include cooling channels in the threaded core. |

Production Improvement: The final mold trial cycle was reduced to 20 seconds, and the customer was highly satisfied. |

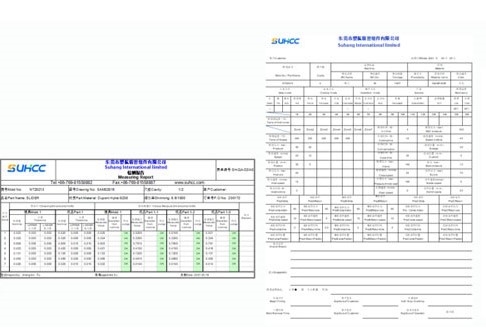

Mold inspection

FAI Report Molding Parameters

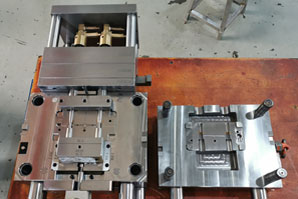

Mold Appearance