Long Carbon Fiber Injection Mold

Long Carbon Fiber Injection Mold Project

This precision-engineered injection mold is designed for LCF40-TPU long carbon fiber parts, with a single cavity and optimized edge gate system. Built with H13 steel and DME-standard mold base, it ensures dimensional accuracy and durability. The mold features pre-deformation design to prevent shrinkage and meet critical 4.243″ assembly requirements. Backed by mold flow analysis and expert tooling, it delivers consistent results on a 200T injection machine. Ideal for high-performance applications requiring tight tolerances and advanced injection mold solutions.

Specification:

| Project name | Long Carbon Fiber Mold | Part Material | LCF40-TPU |

| Part Weight | 181g | Shrinkage Rate | 1‰ |

| Injection Machine | 200T | Injection System | Edge Gate |

| Cavity | 1 | Mold Base Standard | DME Standard |

| Core Material | H13,Insert Material:H13 | Mold Dimensions | 650*450*346MM |

| Mold Weight | 700kg | Manufacturing Lead Time | 5weeks |

| Design Lead Time | 3days |

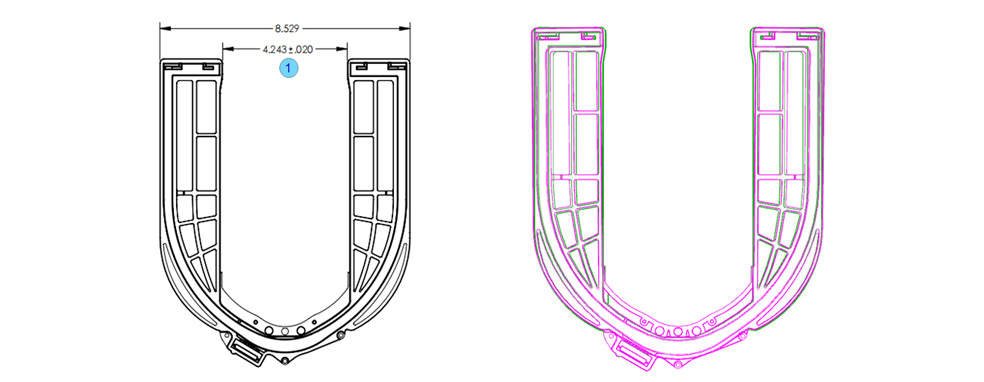

Product Design Optimization

- After joint review by our design team, injection molding engineers, and the customer, we identified that dimension #1 (4.243″) is a critical assembly feature. Considering the potential inward deformation of the part, we applied an outward pre-deformation during the initial design phase to prevent dimensional deviation.

- Through mold flow analysis and our extensive experience in mold design and injection molding, we delivered a mold that exceeded customer expectations. The use of pre-deformation ensured the final part met all dimensional requirements. The customer was highly satisfied with the result.

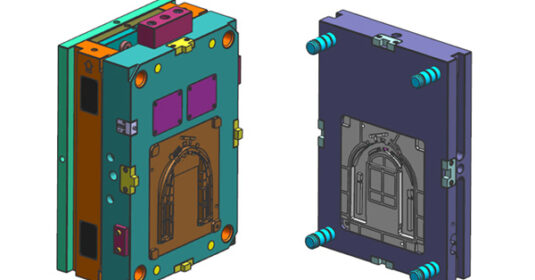

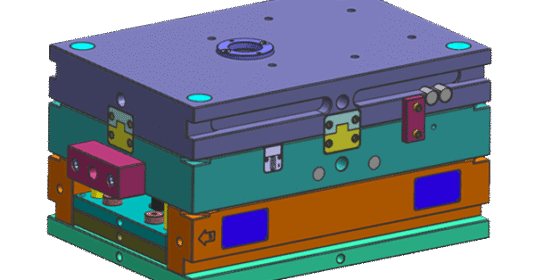

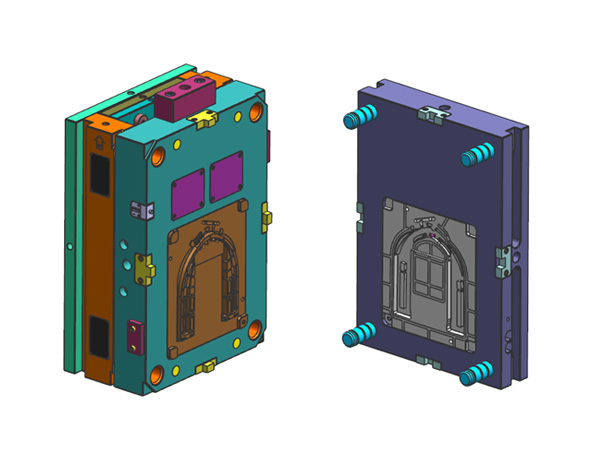

Mold Design

Mold Appearance