Beryllium Copper Mold for POM Parts

Beryllium Copper Mold for POM Parts

This project involves the design and production of a high-precision beryllium copper mold for POM (Polyoxymethylene) parts, specifically for use in switches, relays, and connectors. The mold features a 1×2 cavity configuration and is based on the DME standard, with a P20 steel mold base and C17200 beryllium copper core. The core material’s excellent thermal conductivity, high strength, and corrosion resistance ensure efficient and reliable production. The mold is designed with an effective cooling system to enhance production speed. With a tolerance of ±0.02mm, the mold offers precision and durability for up to 500,000 cycles.

Specification:

| Project name | Beryllium Copper Mold for POM Parts | Part Material | POM |

| Part Weight | 3.2g | Shrinkage Rate | 20‰ |

| Injection Machine | 60T | Injection System | Cold runner, direct gate injection |

| Cavity | 2 | Mold Base Standard | DME Standard |

| Core Material | Imported Beryllium Copper C17200 (Hardness HRC 36-42) | Mold Dimensions | 200 x 200 x 246mm |

| Mold Weight | 85kg | Manufacturing Lead Time | 4weeks |

| Design Lead Time | 3days |

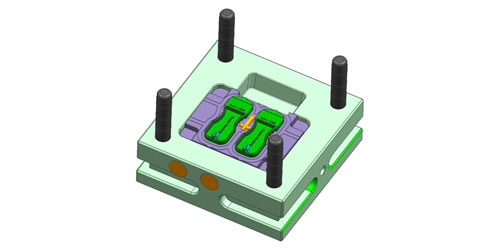

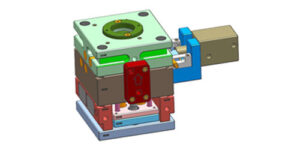

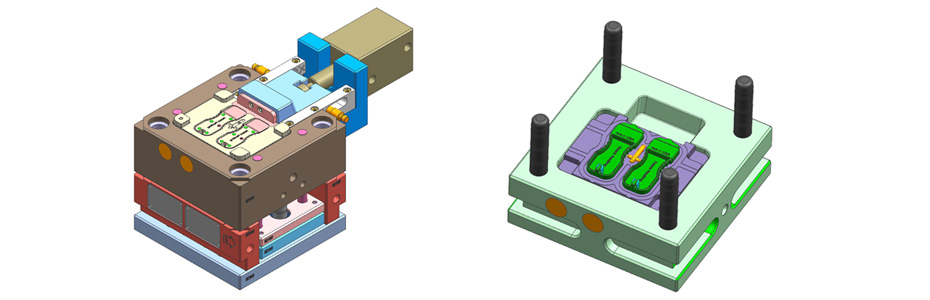

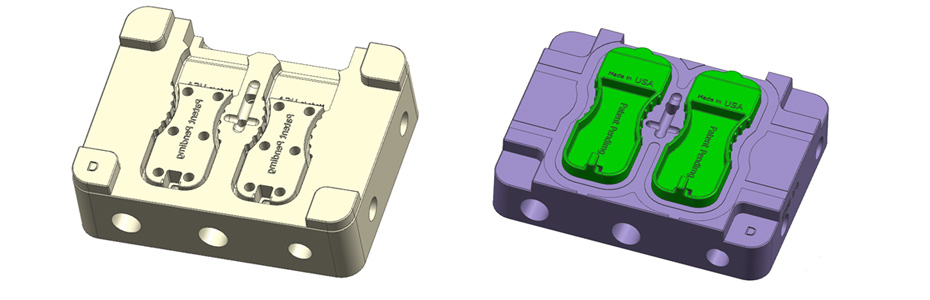

Mold Design

Mold Flow Analysis: The analysis indicated that due to the thick gate, the molding cycle was approximately 45 seconds.

|

Mold Design: Based on the mold flow analysis, we recommend changing the core material to beryllium copper (for its high thermal conductivity), which will allow for rapid cooling of the product during production. |

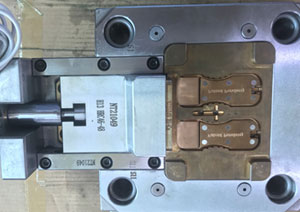

Solution Validation: After the mold was manufactured, we connected the mold’s water channels to chilled water and conducted a trial run.

|

Trial Run Results: The actual molding cycle of the final mold was reduced to 25 seconds, significantly improving the production cycle. The customer has also approved the results. |

Mold information

Mold Design: The mold has a 1×2 cavity configuration. Based on the product structure, the core is made from beryllium copper, which offers high thermal conductivity, high strength, corrosion resistance, and is unaffected by magnetic fields. The core is designed with an efficient cooling system, allowing rapid cooling during injection molding, which improves production efficiency.

Mold Manufacturing: The core is processed using high-speed CNC machining, and holes are finished using slow wire cutting from Japan’s Seibu, ensuring a mold precision of ±0.005mm.

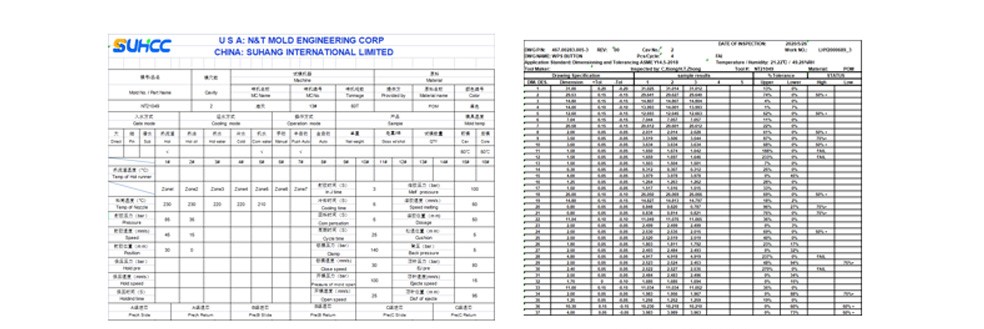

Mold inspection

Molding Parameters FAI Report

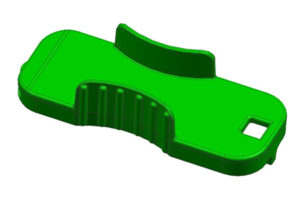

Finished product display

Mold Appearance