You’ve invested in top-tier mold steel (like 8407 or H13), nailed the cooling channel design, and finally got your high-quality molds delivered. But here’s the hard truth: even the most expensive, perfectly engineered mold will fail early if it’s not maintained properly. I’ve seen brand-new molds scratched by careless handling, corroded because someone forgot to dry them, and cracked due to ignored wear signs—all costing clients thousands in unnecessary repairs or replacements.Today, I’m sharing the practical, battle-tested maintenance routine that keeps our molds running for hundreds of thousands of cycles (and helps clients avoid costly downtime). Think of it as giving your mold the “spa day” it deserves—regular care now saves you major headaches later.

I. Why Mold Maintenance Matters More Than You Think

Molds are like athletes: built to perform under pressure, but only if they’re kept in peak condition. Neglecting maintenance shortens lifespan dramatically—here’s what happens when you don’t:

- Corrosion: Moisture (from residual water or humid air) + residual plastic (like PVC’s HCl) = rust spots that weaken the steel.

- Wear & Tear: Tiny scratches from ejector pins, misaligned cores, or abrasive fillers (e.g., glass fibers) accumulate into cracks.

- Thermal Fatigue: Old, clogged cooling channels can’t regulate temperature, causing hot spots that crack the mold over time.

- Contamination: Plastic residue (like burnt POM) builds up in runners/gates, ruining part quality and increasing injection pressure.

Pro tip: A well-maintained mold can last 2–3x longer than a neglected one—even if it’s made from the same steel.

II. Daily/Per-Shot Maintenance (The “Quick Clean” Routine)

These 5-minute steps after every production run prevent 80% of common issues:

1. Remove Residual Plastic Immediately

- Why: Leftover plastic (especially thermosets or high-temp materials like PEEK) hardens and bonds to the cavity, scratching surfaces during the next cycle.

- How:

- Use a soft brass brush (never steel wire!) to gently scrape off large chunks.

- For stubborn residue, heat the mold slightly (to soften the plastic) and wipe with a non-abrasive cloth (microfiber or cotton).

- Never use knives or scrapers—they leave gouges that become crack starters.

2. Blow Out Cooling Channels

- Why: Plastic dust, rust particles, or scale build up in water lines, reducing cooling efficiency and causing hot spots.

- How:

- Disconnect water hoses and blow out channels with compressed air (30–50 PSI).

- For deeper cleaning, flush with warm water + mild detergent (then dry thoroughly to prevent rust!).

- Check for leaks—dripping water = weakened steel over time.

3. Inspect Ejector Pins & Core Surfaces

- Why: Ejector pins rub against the mold every cycle; misalignment or dirt causes scratches that grow into cracks.

- How:

- Visually check pins for scuffs, dents, or uneven movement.

- Lubricate with mold-release spray or light machine oil (avoid excessive oil that attracts dust).

- If pins stick, adjust alignment or replace worn ones immediately.

4. Dry the Mold Completely

- Why: Moisture + steel = rust (especially in humid factories or after waterline cleaning).

- How:

- Wipe all surfaces with a dry, lint-free cloth.

- Store in a dry environment (or use desiccant packs if molds sit unused for days).

III. Weekly/Monthly Maintenance (The “Deep Clean” Checklist)

Every 1–4 weeks (depending on production volume), do this thorough check:

1. Full Visual Inspection

- What to look for:

- Hairline cracks (especially near ejector pins, parting lines, or thin walls).

- Rust spots (even tiny orange flecks mean moisture got in).

- Worn ejector pin holes (enlarged holes = loose pins = part damage).

- Plastic buildup in runners, gates, or venting slots (clogs increase injection pressure).

2. Clean Runners & Gates

- Why: Burnt plastic (from overheating) or leftover material narrows flow paths, forcing higher pressure and stressing the mold.

- How:

- Use a soft brush + mold cleaner solvent (e.g., acetone for most plastics, specialized cleaners for PVC/TPU).

- For severe clogs, insert a nylon or brass wire brush (never steel!) to gently scrub.

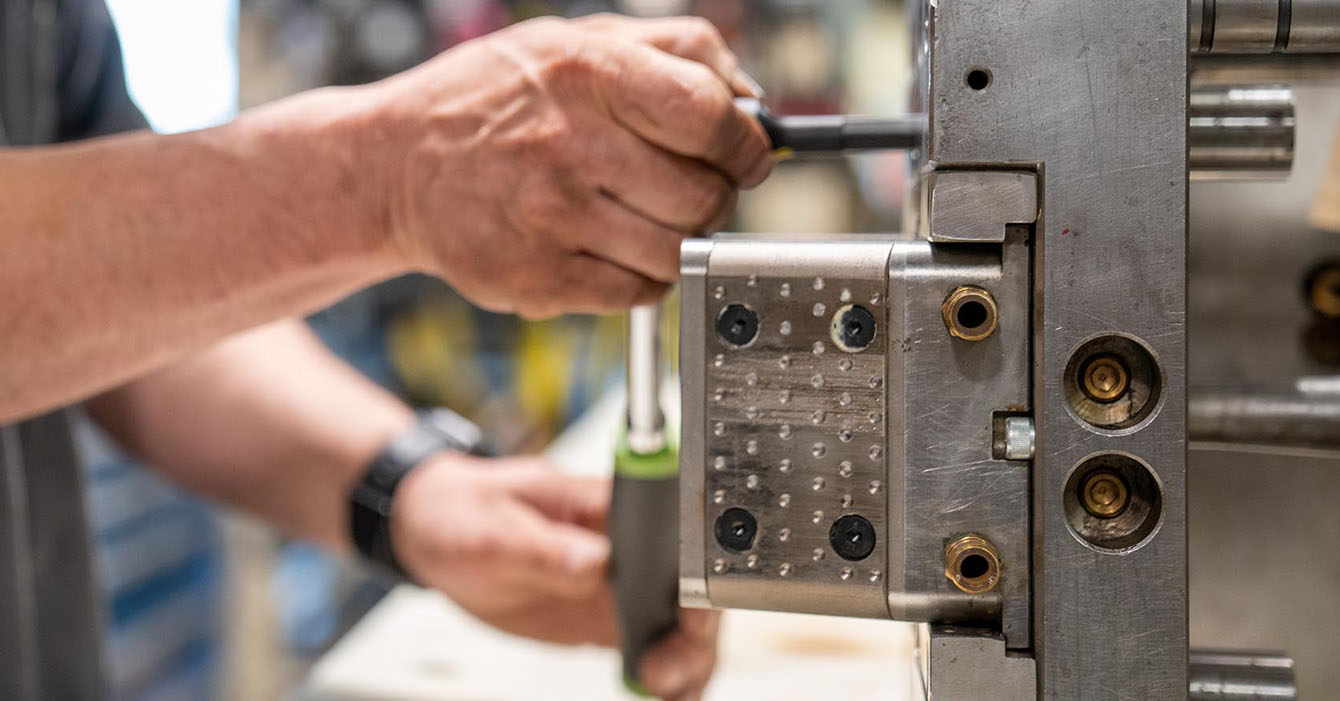

3. Check & Tighten Fasteners

- Why: Vibration from the press loosens bolts over time, misaligning the mold and causing uneven pressure.

- How:

- Use a torque wrench to tighten clamping bolts, guide pins, and ejector plate screws to the manufacturer’s specs.

- Don’t overtighten—excessive force cracks the mold base.

4. Lubricate Moving Parts

- What to lubricate: Guide pins, bushings, ejector plates, and sliding cores.

- What to use: Mold-specific grease (e.g., lithium-based, anti-corrosion formula) or light machine oil.

- Avoid: WD-40 or heavy oils that attract dust and gum up moving parts.

IV. Long-Term Maintenance (Every 10,000–50,000 Cycles)

Think of this as your mold’s “annual physical”—catching issues before they become disasters.

1. Professional Inspection & Polishing

- When: After 10,000–30,000 cycles (or if part quality declines).

- What we do:

- Measure critical dimensions (e.g., cavity depth, gate size) to detect wear.

- Polish worn surfaces (e.g., scratched cavities) to restore smoothness and prevent stress concentrations.

- Repair minor cracks with laser welding or metal spraying (if caught early).

2. Replace Worn Components

- Common culprits: Ejector pins, guide bushes, seals, and springs.

- Why: A single worn ejector pin can scratch the entire cavity; old seals leak water and rust the steel.

- Pro tip: Keep spare parts (like ejector pins) in stock—they’re cheap insurance.

3. Test Cooling System Efficiency

- How: Measure water flow rate (should match original specs) and temperature difference (ideal: ≤10°C between inlet/outlet).

- Fix: Unclog channels, replace damaged hoses, or upgrade to high-flow connectors if needed.

V. Storage & Handling: Don’t Neglect the “Off Duty” Time

Even when molds aren’t in use, they need love:

- Storage: Keep molds in a dry, temperature-controlled room (avoid basements or humid areas). Cover with a breathable cloth (not plastic, which traps moisture).

- Handling: Always use lifting equipment (never manual lifting!) to avoid dropping or bumping. Clean and dry before storing.

- Long-Term Idle: If a mold won’t be used for >30 days, apply a thin rust preventive oil and seal all water ports.

VI. Real Talk: What Happens When You Skip Maintenance?

We once had a client who skipped cleaning for 6 months after switching to a glass-filled nylon. The result?

- Ejector pins corroded → scratched the cavity → parts had visible marks.

- Cooling channels clogged → hot spots caused cracks → mold failed at 45,000 cycles (should’ve lasted 200,000+).

- Repair cost: 12,000(vs.200/month if they’d done weekly cleaning).

Lesson: A 10-minute daily routine saves thousands in long-term costs.

VII. Your Mold Maintenance Checklist (Print & Post Near Your Press!)

✅ After Every Shot: Remove plastic, blow out waterlines, inspect ejector pins, dry mold.

✅ Weekly: Visual inspection, clean runners, tighten bolts, lubricate moving parts.

✅ Monthly: Measure dimensions, replace worn parts, test cooling efficiency.

✅ Every 10K–50K Cycles: Professional inspection, polishing, and component replacement.

✅ Storage: Dry, covered, and protected from drops.

Final Thought: Your mold is an investment—not just in steel, but in your production reliability. Treat it like a partner: give it the care it needs, and it’ll keep churning out perfect parts for years.Need a customized maintenance plan for your specific mold? Share your steel type and production details, and I’ll help you build one. Because remember: even the best design needs love to perform at its peak. 💙(P.S. Want a printable version of this checklist? Comment below, and We’ll email it to you!)