Explore the differences between Metal Injection Molding (MIM) and Die Casting. Learn their processes, advantages, and ideal applications in manufacturing.

IMD vs IML: Understanding the Differences in Injection Molding Decoration Techniques

Learn the difference between IMD (In-Mold Decoration) and IML (In-Mold Labeling). Understand their processes, applications, and key benefits in injection molding.

CNC Machining: Maximum Extents

Find the maximum extents of plastic and metal materials available for CNC milled and turned parts. CNC Milling Material Maximum Extents ABS Max. Depth: 3.75 in. (95.25mm) ABS Flame Retardant Max. Depth: 1.75 in. (44.45mm) Aluminum 6061-T651 Max. Depth: 3.75 in….

Material Alternatives for Plastic Injection Molding

During material supply shortages, consider these resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics Navigating supply chain issues is a constant challenge, especially in times of material shortages. So we looked at the more commonly used materials and…

Injection Molding Material Comparison Guide

Choose from hundreds of manufacturing materials including various grades of thermoplastics, metals, and elastomers. When selecting a material, consider the material properties, manufacturability characteristics, cosmetic appearance, and cost. For milling and turning dimensions by material, please see maximum part extents for machining. Additional…

Design Guidelines: Plastic Injection Molding

Size Maximum Dimensions IN MM SIZE 18.9 in. x 29.6 in. x 8 in. 480mm x 751mm VOLUME 59 cu. in. 966,837 cu. mm DEPTH 4 in. from parting line 101mm from parting line Up to 8 in. if parting line…

Injection Molding Material Selection Guide

This guide to thermoplastics and injection molding material selection is aimed at an engineer who plans to quantitatively analyze a part, determine loads, stresses, strains, and environments and make an optimal material decision based on the analysis. If life safety is…

Injection Molding: A Beginner’s Guide

What is Injection Molding? Injection molding is process tailored for producing large volumes of parts. Compared to other manufacturing technologies—like CNC machining and 3D printing—it requires an upfront, capital investment into tooling. But individual piece-part price will be substantially less when…

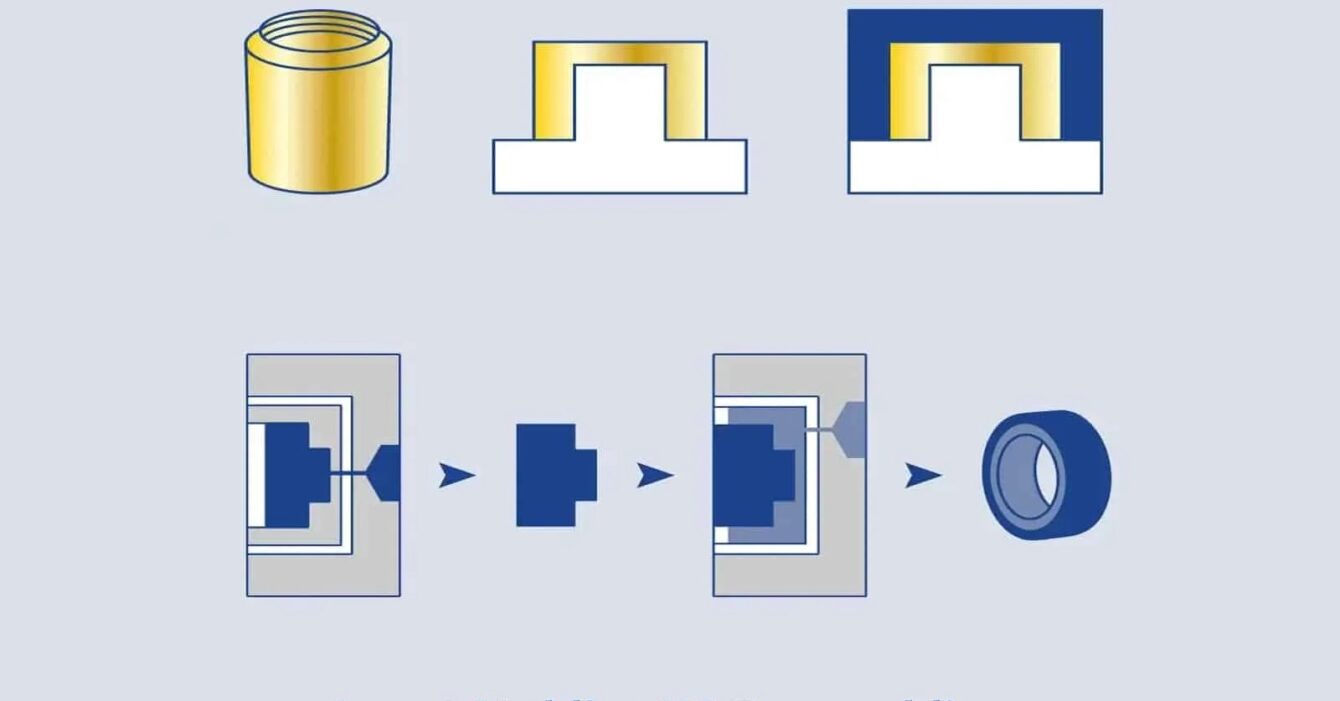

Design Guidelines: Overmolding & Insert Molding

SYNOR’s basic guidelines for overmolding and insert molding include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

Design Guidelines: Overmolding & Insert Molding

SYNOR’s basic guidelines for overmolding and insert molding include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Size Maximum Dimensions IN MM SIZE 18.9 in. x 29.6 in. x 8 in. 480mm x…