Here’s a hard truth: Even the best steel fails if your cooling channels suck. I’ve seen $50,000 H13 molds crack after 20,000 shots because the water lines were poorly placed. Conversely, a well-designed cooling system can extend a basic steel’s life by 30–50%. Let’s break down how to design channels that complement your mold steel, avoid common mistakes, and keep your molds running longer.

I. Why Cooling Channels Matter (A Lot)

Die-casting molds endure constant thermal shock—molten metal heats them to 300–500°C (570–930°F), then they cool rapidly. This cycle creates thermal fatigue (micro-cracks from expansion/contraction). Cooling channels regulate temperature to:

- Prevent hot spots (localized overheating leads to cracks).

- Reduce thermal stress (even cooling minimizes warping).

- Improve cycle times (faster cooling = more shots/hour).

Your steel’s job is to resist wear and heat; your channels’ job is to keep the steel cool and stable.

II. Matching Channels to Your Steel Type

1. H13 (Budget-Friendly Steel)

Challenge: Prone to thermal fatigue if overheated.

Channel Strategy: “Dense and Even” – Focus on uniform cooling to prevent hot spots.

▶ How to do it:

- Core areas (hottest spots): Channels 8–12mm from the cavity surface, spaced 15–20mm apart.

- Gate areas (where metal first enters): Dedicated channels 10–15mm from the sprue.

- Slides/guides: Add channels to slider cores (they trap heat).

- Goal: Cover 80% of the cavity surface. Avoid “cold zones” where no water flows.

Fix: A client’s H13 mold cracked at the core after 30,000 shots. We added 3 spiral channels around the core (18mm spacing), and lifespan jumped to 80,000 shots.

2. 8407 (Long-Life Steel)

Challenge: Already great at resisting fatigue, but needs channels to maximize its potential.

Channel Strategy: “Balanced Temperature” – Focus on minimizing temperature differences across the mold.

▶ How to do it:

- General density: Slightly fewer channels than H13 (8407 handles heat better), but key areas (core, gate) spaced 20–25mm apart.

- Temperature equilibrium: Connect hot zones (near the gate) to cooler zones (edges) with “loop” channels to prevent >50°C differences.

- Deep cavities: Add channels to the bottom of thick sections (they cool slower).

Success story: An AC housing mold with 8407 and optimized channels ran 220,000 shots. The secret? Even cooling kept the entire mold within 30°C.

3. DAC (Thin-Wall Specialist)

Challenge: Thin sections (0.3–0.5mm) need precise cooling to avoid filling defects.

Channel Strategy: “Close to Thin Walls, But Not Too Close” – Cool thin areas gently to prevent warping.

▶ How to do it:

- Thin-wall zones: Channels 6–10mm from the cavity (closer than usual, but not touching). Water temp: 25–40°C (avoid freezing the mold).

- Thick-wall zones: Fewer channels (thick areas cool slower naturally).

- Goal: Balance cooling between thin and thick sections to prevent uneven shrinkage.

Lesson learned: A phone case mold with DAC initially had channels 5mm from thin walls, causing warping. Moving them to 8mm and setting water temp to 30°C fixed the issue—and extended life to 100,000 shots.

4. S136 (Corrosion-Resistant Steel)

Challenge: Prone to clogged channels from corrosive plastic residues.

Channel Strategy: “Clean and Gentle” – Prevent blockages and avoid extreme cooling.

▶ How to do it:

- Channel material: Use stainless steel or copper fittings (resist corrosion from PVC/CPVC debris).

- Channel design: Avoid sharp bends (use rounded corners to prevent buildup).

- Goal: Ensure all plastic-contact areas are cooled, but keep water temp stable (avoid sudden shocks).

Fix: A PVC pipe mold with S136 had clogged channels after 6 months. Switching to stainless fittings and rounded channels kept the mold running for 500,000 shots.

III. Universal Cooling Channel Mistakes to Avoid

No matter your steel, these errors will ruin your mold:

1.Channels too far from the cavity (>15mm) → Heat doesn’t transfer effectively.

2.Uneven spacing (some areas 5mm apart, others 30mm) → Hot spots cause cracks.

3.No channels near the gate → The hottest spot fails first.

4.Slides without water → Trapped heat leads to premature wear.

5.Using icy water (<20°C) or fluctuating temps → Thermal shock cracks the mold.

IV. The Engineer’s Cheat Sheet

**“Steel sets the base, channels control the fate.

Core gets dense flow, gate needs its own fate.

Thin walls stay close, thick walls take it slow.

No dead zones, no spikes—that’s how molds grow!”**

Simple rules:

- H13? Pack channels everywhere to fight heat.

- 8407? Balance cooling for long-term stability.

- DAC? Protect thin walls with gentle, close cooling.

- S136? Keep channels clean and temps steady.

V. Final Advice

The best mold isn’t just about expensive steel—it’s about smart design. Match your steel to your production needs, then optimize cooling to match. Need help designing channels for your next mold? Drop your specs, and I’ll walk you through it.(Next time: How to maintain your molds for maximum lifespan—because even the best design needs love!)

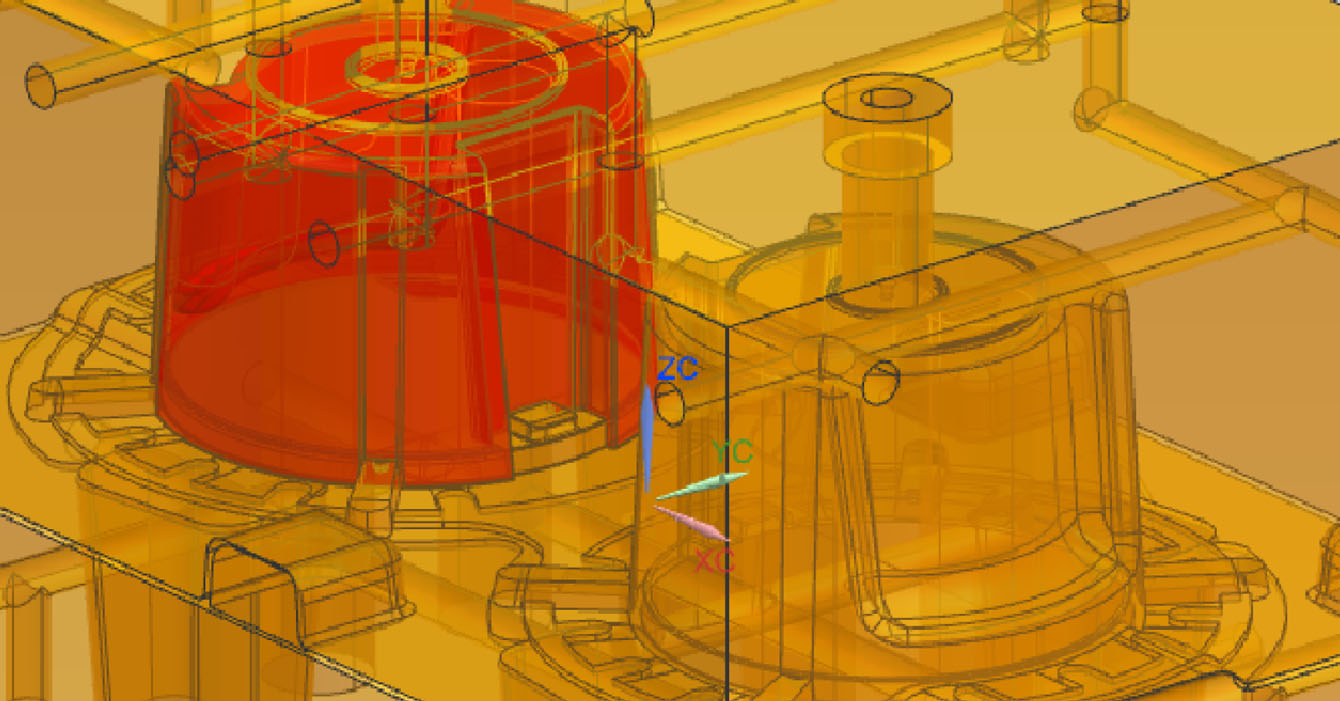

Bonus: Want to see channel layouts for H13 vs. 8407? Or thermal simulation results? Comment below—I’ll share our shop’s visuals.