In the world of manufacturing, both Metal Injection Molding (MIM) and Die Casting are popular methods for producing high-precision metal parts. While they both involve molding processes to shape metal components, they differ in materials, processes, and ideal applications. Understanding these differences is crucial for selecting the right method based on part requirements such as complexity, size, strength, and cost.

This article will explore MIM and Die Casting, compare their advantages and disadvantages, and provide insights into the types of applications each method is best suited for.

What is Metal Injection Molding (MIM)?

Metal Injection Molding (MIM) is a manufacturing process used to produce small, complex, high-precision metal parts. It is similar to plastic injection molding, but instead of plastic, a metal powder mixed with a binder is injected into a mold. After injection, the binder is removed, and the metal part is sintered in a furnace to achieve its final strength.

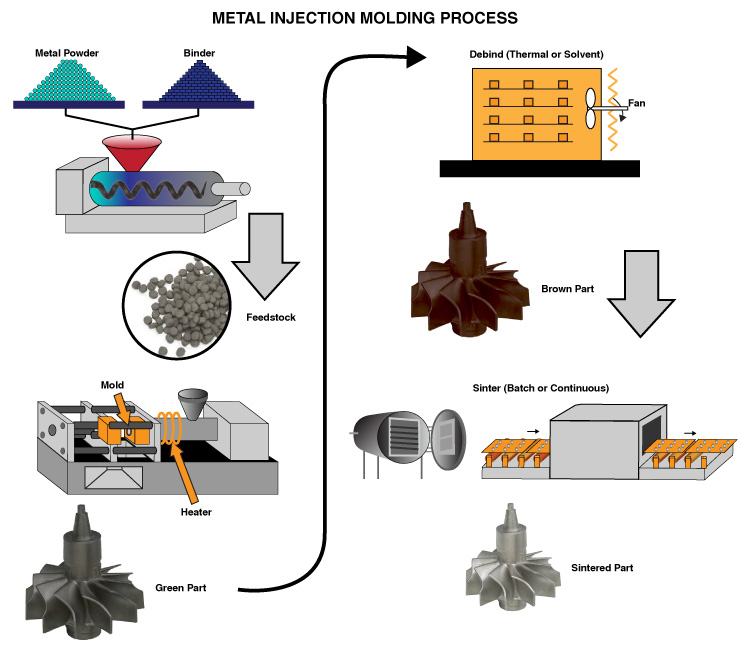

How MIM Works:

1.Powder Preparation: Metal powders (such as stainless steel, titanium, or other alloys) are mixed with a binder material to form a feedstock.

2.Injection Molding: The feedstock is injected into a mold cavity, where it takes the shape of the part.

3.Debinding: The binder is removed through a chemical or thermal process.

4.Sintering: The part is heated to a high temperature, causing the metal particles to fuse together, resulting in a solid, fully metal part.

Advantages of MIM:

- Complex Geometries: MIM allows for intricate and complex part designs that are difficult or impossible to achieve with other metalworking methods.

- High Precision: MIM parts can achieve tight tolerances and high-dimensional accuracy, which is essential for components used in industries like aerospace, medical devices, and electronics.

- Material Variety: MIM supports a wide range of materials, including stainless steel, titanium, tungsten, and other high-performance alloys.

- High Production Efficiency: Once the mold is created, MIM allows for high-volume production with consistent quality.

Applications of MIM:

- Medical devices (e.g., surgical instruments, implants)

- Aerospace components

- Automotive parts (e.g., small gears, connectors)

- Consumer electronics (e.g., mobile phone components)

What is Die Casting?

Die Casting is a process in which molten metal is injected into a steel mold (die) under high pressure. The mold is typically made of high-strength steel, and the molten metal is forced into the mold cavities to form the desired shape. The metal then cools and solidifies in the mold, and the part is ejected.

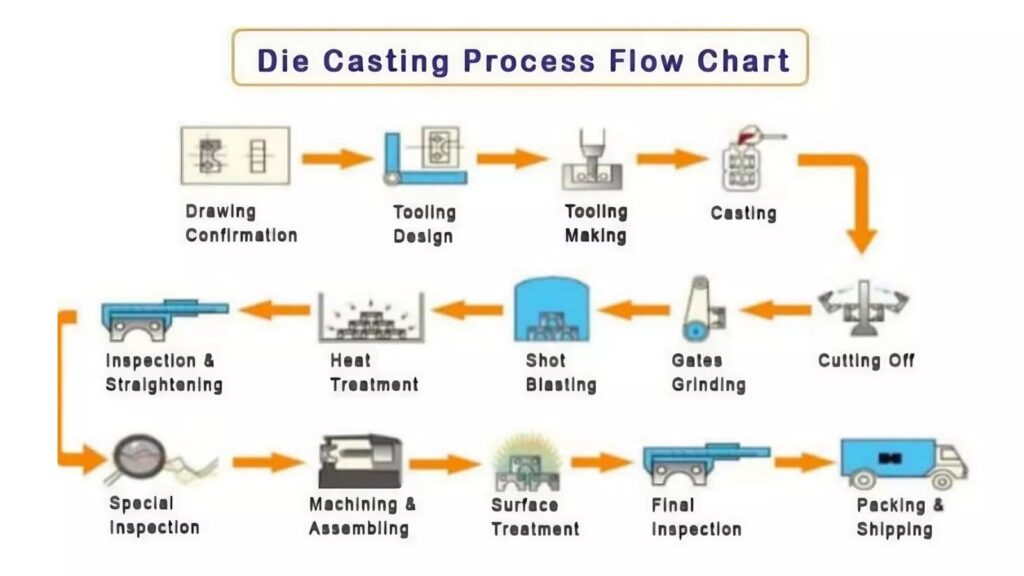

How Die Casting Works:

1.Molten Metal Preparation: Metal (typically aluminum, zinc, or magnesium alloys) is heated to a molten state.

2.Injection into Die: The molten metal is injected into a steel die under high pressure, filling the cavity quickly and precisely.

3.Cooling and Ejection: The metal solidifies in the mold, and the part is ejected once it has cooled.

Advantages of Die Casting:

- High-Speed Production: Die casting is ideal for producing large quantities of parts quickly due to the fast cycle times.

- Dimensional Accuracy: Die-cast parts have excellent dimensional consistency and can achieve tight tolerances.

- Smooth Surface Finish: The die-cast process typically results in parts with a smooth, high-quality surface finish.

- Material Versatility: Die casting works well with metals that can withstand high temperatures, such as aluminum, zinc, and magnesium alloys.

Applications of Die Casting:

- Automotive parts (e.g., engine components, transmission housings)

- Electronics enclosures (e.g., computer casings, mobile phone frames)

- Consumer products (e.g., hardware, door handles)

- Industrial components (e.g., gears, valves)

MIM vs Die Casting: Key Differences

While both MIM and Die Casting are used for producing metal parts, they differ in the materials used, the processes, and the type of components they are best suited for. Below is a comparison of the two:

| Feature | Metal Injection Molding (MIM) | Die Casting |

|---|---|---|

| Materials Used | Metal powders (stainless steel, titanium, etc.) | Molten metals (aluminum, zinc, magnesium, etc.) |

| Complexity | Suitable for highly complex parts with intricate geometries | Best for simpler, medium to high-volume parts |

| Precision | High precision with tight tolerances | High precision but generally less complex than MIM |

| Cycle Time | Slower (due to sintering process) | Faster (high-speed production) |

| Production Volume | Ideal for medium to high volumes | Best for high-volume production |

| Surface Finish | Can achieve high-quality finishes, but post-processing may be needed | Smooth surface finish with minimal post-processing |

| Part Size | Typically small to medium-sized parts | Typically medium to large parts |

| Material Variety | Wide range of metals, including high-performance alloys | Primarily non-ferrous metals, such as aluminum and zinc |

| Cost Efficiency | Higher initial tooling costs, but efficient for high volumes | Cost-effective for large volumes, but material limitations exist |

| Applications | Medical devices, aerospace, electronics, automotive components | Automotive, electronics, consumer products, industrial components |

Advantages of MIM Over Die Casting

- Complex Designs: MIM can handle highly intricate shapes and geometries that would be difficult or impossible to achieve with die casting. This makes MIM ideal for parts like medical implants or precision components for electronics.

- Material Flexibility: MIM offers a broader selection of materials, including specialized alloys and composites, which can meet the demanding requirements of industries like aerospace or medical device manufacturing.

- Tighter Tolerances: MIM can achieve tighter dimensional tolerances, which is crucial in applications where precision is paramount.

Advantages of Die Casting Over MIM

- Faster Cycle Time: Die casting offers quicker production cycles, which is ideal for large-volume production runs. This makes it a better choice for industries that require fast turnaround times, such as the automotive and consumer goods sectors.

- Cost-Effective for High Volumes: Die casting is generally more cost-effective for producing large quantities of parts due to its faster cycle time and lower material costs compared to MIM.

- Larger Part Sizes: Die casting is better suited for producing larger parts than MIM, which typically produces smaller components.

Choosing Between MIM and Die Casting

When choosing between Metal Injection Molding (MIM) and Die Casting, several factors must be considered:

- Part Complexity: If the part requires complex geometries, intricate features, or tight tolerances, MIM is the better choice.

- Production Volume: Die casting is ideal for high-volume production runs, especially for medium to large parts. MIM is more suitable for medium to high volumes with smaller parts.

- Material Requirements: If you need specific, high-performance materials, MIM offers more material flexibility. Die casting, on the other hand, is limited to a range of alloys like aluminum, zinc, and magnesium.

- Cycle Time: For fast production cycles and quick turnaround, die casting has an advantage due to its shorter cycle time.

Both Metal Injection Molding (MIM) and Die Casting offer significant advantages for manufacturing metal parts, but they are suited to different types of applications. MIM is ideal for producing small, complex parts with high precision and material flexibility, making it perfect for industries like medical, aerospace, and electronics. Die casting, on the other hand, is better suited for larger, simpler parts that require fast production cycles, making it ideal for automotive, industrial, and consumer products.

Understanding the key differences and benefits of MIM and Die Casting will help you select the right manufacturing process based on your part design, production volume, material needs, and cost considerations.