In the world of injection molding, the term “core” plays a vital role in creating complex and precise parts. Simply put, the core is a component of the mold used to form the internal geometry of a part during the molding process. Together with the cavity, the core defines the final shape of the molded part, especially in parts that require hollow sections, intricate designs, or undercuts.

This article will delve into what a core is in injection molding, its different types, its function within the mold, and how it contributes to producing high-quality, complex parts efficiently.

What is a Core in Injection Molding?

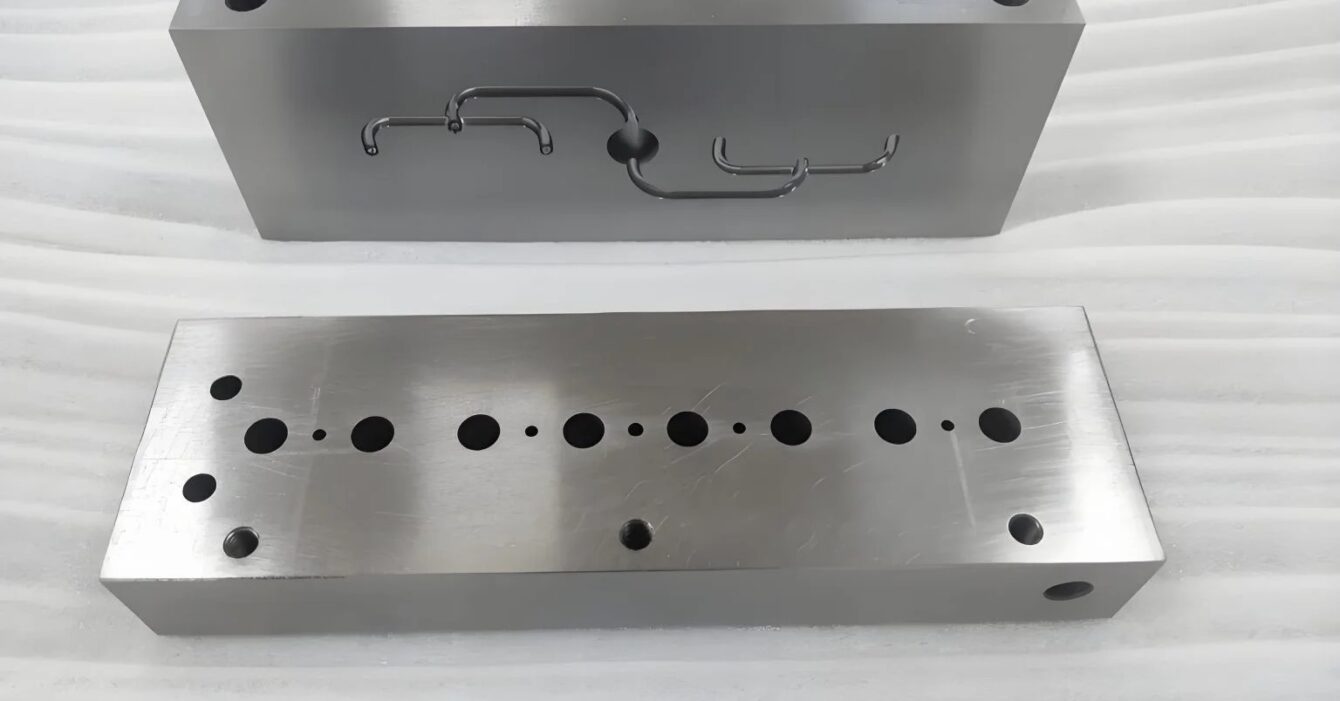

In injection molding, the core is a section of the mold that forms the internal features of the molded part. Typically, the mold consists of two primary components: the core and the cavity.

- Cavity: The external part of the mold that shapes the outer surface of the part.

- Core: The internal part of the mold that forms the inner geometry, such as holes, channels, and other internal features.

The core is typically made from durable materials such as steel or aluminum, which can withstand high injection pressures and temperatures. It is inserted into the mold cavity and works in tandem with the cavity to shape the molten material as it cools and solidifies, giving the final part its internal structure.

Core and Cavity Relationship

To better understand the role of the core, it’s essential to consider its relationship with the cavity. When the mold is closed, the cavity and core work together to form the desired part. After the injection of molten material, the material fills the cavity and surrounds the core, forming the external shape of the part while the core creates the internal features.

Types of Cores in Injection Molding

Cores can take several forms depending on the specific part design and functionality required. The three most common types of cores in injection molding are:

1. Solid Cores

- Description: A solid core is a basic design where the core is a solid piece that does not contain any internal features like holes or channels. It is often used for parts with simple internal geometries or when the mold does not require complex features.

- Applications: Used for simple, non-hollow parts or those with minimal internal features.

- Advantages: Easier to manufacture and design, lower cost, and shorter production time.

2. Hollow Cores

- Description: A hollow core includes internal channels or cavities, enabling the production of hollow sections within the molded part. These types of cores are commonly used to create lightweight parts or components that require internal features like pipes, ducts, or cooling channels.

- Applications: Ideal for creating parts with hollow features, such as containers, piping systems, or components in automotive or consumer products.

- Advantages: Enables the creation of complex internal geometries and reduces material usage, making parts lighter.

3. Movable or Collapsible Cores

- Description: A movable core is used when a part design requires an undercut or internal feature that would normally make the part difficult to eject. These cores are designed to shift or collapse during the molding process, allowing the mold to release the part more easily after the material has cooled.

- Applications: Commonly used in parts with undercuts, threaded inserts, or complex features that cannot be formed with a traditional core.

- Advantages: Allows for the production of parts with complex geometries and undercuts without compromising the part’s ejection or mold integrity.

Functions and Benefits of the Core in Injection Molding

The core plays a critical role in determining the final characteristics of the molded part. Here are the primary functions and benefits of using a core in injection molding:

1. Creating Internal Geometries and Features

The core is essential for forming complex internal features such as holes, channels, and cavities. This is especially important for parts used in industries like automotive, aerospace, and medical devices, where intricate internal geometries are often required for functionality, such as fluid channels or cooling ducts.

2. Enabling Undercuts

In injection molding, undercuts are features that cannot be molded through a straight ejection. The core is used to form undercuts by allowing certain sections of the mold to move or collapse, making it possible to produce parts with complex, interlocking shapes or features like threaded inserts or snap-fits.

3. Reducing Part Weight

By incorporating hollow cores, manufacturers can reduce the weight of molded parts without sacrificing strength. This is particularly valuable in industries like automotive and electronics, where reducing weight is crucial for efficiency, fuel economy, or ease of handling.

4. Improving Part Functionality

The core is essential for producing parts that have functional internal features, such as cooling channels, ventilation holes, or fluid pathways. These features are critical in many industrial parts, such as heat exchangers, pumps, and other components that require fluid or air circulation for proper operation.

5. Enhancing Mold Efficiency

The design of the core can also contribute to mold efficiency by enabling multi-functionality. For example, a movable core can allow the mold to create complex features that would otherwise require multiple mold components, streamlining the production process.

Design Considerations for Cores in Injection Molding

Designing an effective core involves several factors to ensure successful molding and optimal part quality. Key design considerations include:

1. Material Selection

The material chosen for the core must be durable and able to withstand high temperatures and pressures during the molding process. Steel and aluminum are commonly used for core materials because of their strength, heat resistance, and ability to maintain dimensional stability.

2. Core Venting

Proper venting is essential to allow air and gases to escape from the cavity during the molding process. Without proper venting, the trapped air can lead to defects like burns or incomplete parts. Careful venting around the core ensures that the mold fills evenly and that any gases or air trapped inside can escape efficiently.

3. Core Ejection Mechanism

When the part is finished cooling, the core must be designed to allow for easy ejection of the part. This may involve using collapsible or movable cores that shift to release the part without damaging it. The ejection mechanism should also prevent any distortion or marking of the part’s internal features.

4. Tolerances and Fit

To ensure a precise fit between the core and cavity, the mold must be manufactured with tight tolerances. Even slight misalignment can lead to defects in the molded part, such as mismatched surfaces or imperfect internal features.

Common Issues with Cores in Injection Molding

While the core is a crucial component of mold design, it can introduce certain challenges during the molding process. Some common issues include:

1. Core Shift

If the core is not properly aligned during the molding process, it can shift, leading to misalignment of internal features and defects in the molded part. Properly designing the core and ensuring accurate mold setup is critical to prevent this issue.

2. Core Wear

Cores, especially those used in high-volume production, can wear over time due to constant exposure to heat and pressure. Regular maintenance and replacement of worn cores are essential to maintaining mold performance.

3. Cooling Problems

Improper cooling of the core can result in uneven part cooling, leading to warping, internal stress, or defects. Ensuring proper cooling channels around the core is essential for achieving consistent part quality.

The core is a critical component in injection molding that plays an essential role in shaping the internal features of a part. Whether used for creating hollow sections, undercuts, or functional internal channels, the core enables manufacturers to produce complex and high-performance parts efficiently. By understanding the various types of cores, their functions, and the best practices for design, manufacturers can optimize mold performance, improve part quality, and reduce production costs.