In the world of injection molding, the appearance, feel, and performance of the final product are often just as important as its functionality. One of the most significant aspects of enhancing a product’s visual appeal and surface characteristics is mold texturing. Mold texturing refers to the process of adding patterns, textures, or surface finishes to a mold cavity to create distinctive features on the molded part.

This guide will explore mold texturing in injection molding, including the types of textures, the techniques used, the benefits and challenges, and how texturing can improve both the aesthetic and functional properties of your molded parts.

What is Mold Texturing?

Mold texturing in injection molding involves altering the surface of the mold cavity to create a specific pattern, texture, or finish on the surface of the molded part. Texturing can range from simple patterns like matte finishes to more intricate designs, such as brushed or embossed effects. These surface finishes can significantly enhance the product’s appearance and functionality, providing benefits in terms of aesthetics, tactile properties, and even durability.

Textured molds are commonly used for consumer products, automotive parts, and electronics, where surface appearance and feel are critical factors.

Why Use Mold Texturing?

- Improved Aesthetics: Textured surfaces can give the product a more sophisticated or unique look.

- Enhanced Durability: Certain textures can increase the scratch resistance and durability of the molded part.

- Functional Benefits: Texturing can improve grip, reduce glare, or provide anti-slip properties.

- Brand Differentiation: Custom textures are often used to make a product stand out in the market.

- Concealment of Imperfections: Textured surfaces can help hide minor surface imperfections like scratches or marks, providing a cleaner look.

Types of Mold Textures

There are several types of textures that can be applied to injection molds, each offering different visual and functional outcomes. Some of the most common types include:

1. Matte Finish

- Characteristics: Smooth, non-reflective finish that provides a soft, satin appearance.

- Applications: Often used for consumer electronics, automotive parts, and household goods.

- Benefits: Minimizes the appearance of fingerprints and scratches, providing a clean, modern look.

2. Glossy Finish

- Characteristics: A shiny, reflective surface finish.

- Applications: Used for high-end products like smartphone housings or glossy automotive trim.

- Benefits: Provides a sleek and polished appearance, adding a touch of luxury.

3. Texture Patterns (e.g., Orange Peel)

- Characteristics: A pattern that mimics the texture of an orange peel, with small, uniform bumps.

- Applications: Common in automotive parts, appliances, and electronics.

- Benefits: Offers a subtle texture that improves grip and minimizes the appearance of imperfections.

4. Bead Blasted Texture

- Characteristics: Created by blasting the surface with small beads to create a fine, uniform texture.

- Applications: Often used in industrial and aerospace parts.

- Benefits: Provides a clean, non-reflective texture that enhances durability and provides a professional appearance.

5. Etched/Engraved Patterns

- Characteristics: Highly detailed and customized designs that can range from simple logos to intricate artwork.

- Applications: Frequently used in luxury items, electronics, and packaging.

- Benefits: Offers high levels of customization and branding opportunities while adding unique visual appeal.

6. Brushed Metal Finish

- Characteristics: A fine linear pattern created by brushing the mold surface with abrasive materials.

- Applications: Used for metal-like finishes on plastic parts, often in the automotive or appliance sectors.

- Benefits: Provides an elegant, textured finish that mimics real metal and enhances the product’s tactile feel.

7. Anti-Slip Texture

- Characteristics: A texture that creates grip on the surface, often using raised patterns.

- Applications: Found in parts such as tool handles, grips, and safety equipment.

- Benefits: Enhances user safety and comfort by improving grip.

Techniques for Creating Mold Textures

The process of adding texture to a mold cavity can be achieved through various techniques. The choice of technique largely depends on the desired texture, material, and part specifications. The most common methods include:

1. Mechanical Texturing

- Description: Involves the use of abrasive tools or machines to create a specific pattern on the mold’s surface.

- Tools: Sandpaper, rotary tools, or CNC machines can be used to manually or automatically create textures.

- Applications: Suitable for standard textures, like matte or bead-blasted finishes.

2. Chemical Etching

- Description: Uses chemical reactions to etch a pattern or texture onto the mold surface. Acidic solutions are applied to the mold to eat away at certain areas, creating the desired texture.

- Applications: Used for intricate or custom designs, such as logos, artwork, or complex patterns.

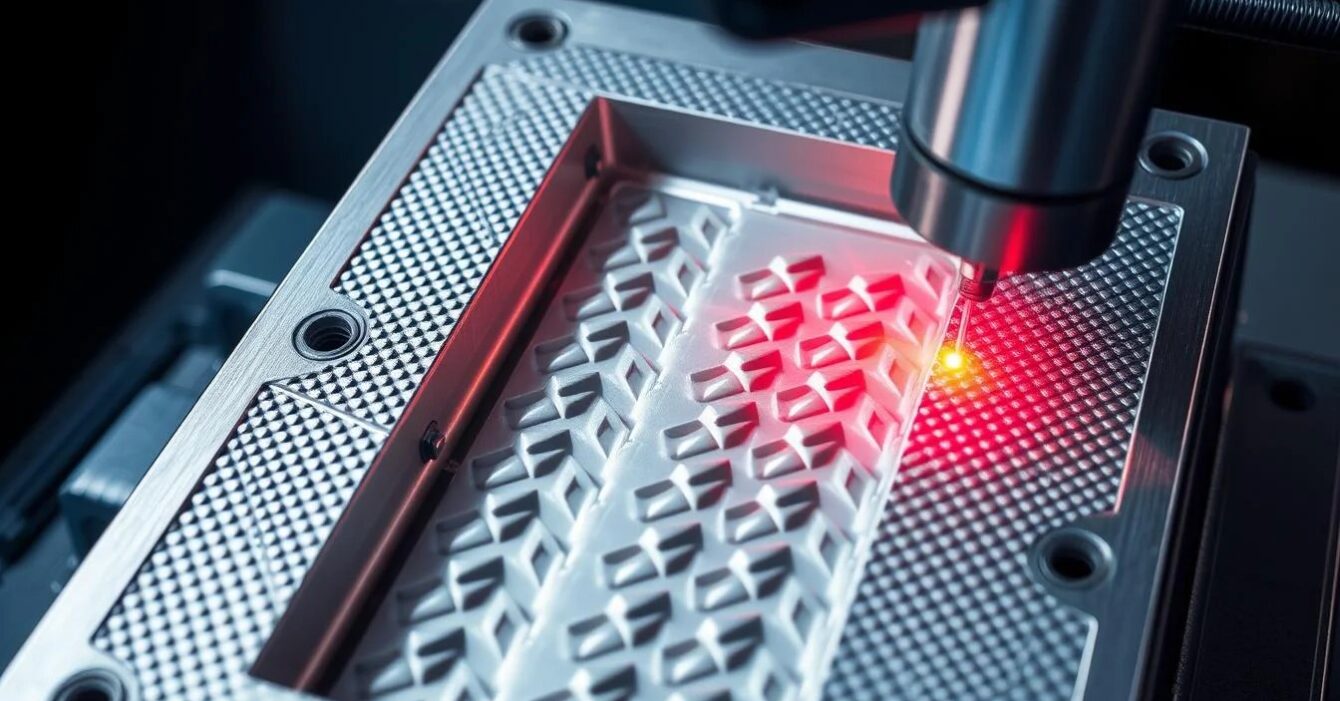

3. Laser Engraving

- Description: Uses focused laser beams to precisely engrave detailed patterns on the mold cavity.

- Applications: Ideal for creating fine, high-precision textures, logos, and very detailed surface designs.

- Benefits: Offers high precision and fine details that are hard to achieve with mechanical techniques.

4. EDM (Electrical Discharge Machining)

- Description: Involves the use of electrical sparks to create small indentations on the mold surface, producing highly detailed textures.

- Applications: Suitable for intricate textures that require precision, such as those used in luxury or high-performance parts.

- Benefits: Can achieve very fine, detailed patterns that are hard to replicate using other methods.

5. Mold Coatings

- Description: Special coatings or treatments can be applied to molds to produce a desired texture or finish. These can be temporary or permanent.

- Applications: Often used in molds requiring repeated texturing or when a specific finish is needed for a batch of parts.

- Benefits: Offers flexibility and ease of maintenance for parts that require regular texture changes.

Advantages of Mold Texturing in Injection Molding

Adding texture to the injection mold offers several benefits that can significantly improve the final product:

1.Aesthetic Appeal: Textured surfaces can enhance the look of the product, making it stand out in the market.

2.Functional Improvements: Texturing can improve a product’s grip, reduce gloss, and hide imperfections.

3.Improved Durability: Some textures, like those that replicate a brushed metal finish, can improve the scratch resistance and wearability of the part.

4.Branding Opportunities: Custom textures and patterns are an excellent way to incorporate logos or design elements into the part, providing brand differentiation.

Challenges of Mold Texturing

While mold texturing offers numerous benefits, there are also some challenges associated with the process:

1.Increased Costs: The additional steps involved in creating textures, especially for complex designs, can add to the mold-making and part-production costs.

2.Longer Cycle Times: Some textures, particularly those with intricate designs or fine details, can slow down the injection molding process.

3.Tool Wear: The textured surfaces can cause increased wear on the mold over time, requiring more frequent maintenance or replacement.

Mold texturing is an essential technique in injection molding, enabling manufacturers to create parts with enhanced aesthetics, functionality, and durability. By choosing the right texture and technique, businesses can improve product quality, differentiate themselves in the market, and meet the specific needs of their customers. Whether for enhancing grip, reducing glare, or adding intricate designs, mold texturing plays a crucial role in achieving high-quality, visually appealing, and functional parts.