Confused by injection mold quotations? Learn how material costs, machining, design, and hidden fees impact pricing for custom injection molds. Decode quotes to negotiate smarter and avoid budget overruns in your injection molding projects.

10 Common Injection Molding Defects by Material Type – Quick Troubleshooting Guide

Struggling with injection molding defects? This material-specific quick guide covers the 10 most common issues—from short shots to silver streaks—across plastics like ABS, PC, PP, glass-filled PA66, and PVC. Tailored fixes for each material help you boost yield in custom injection molding.

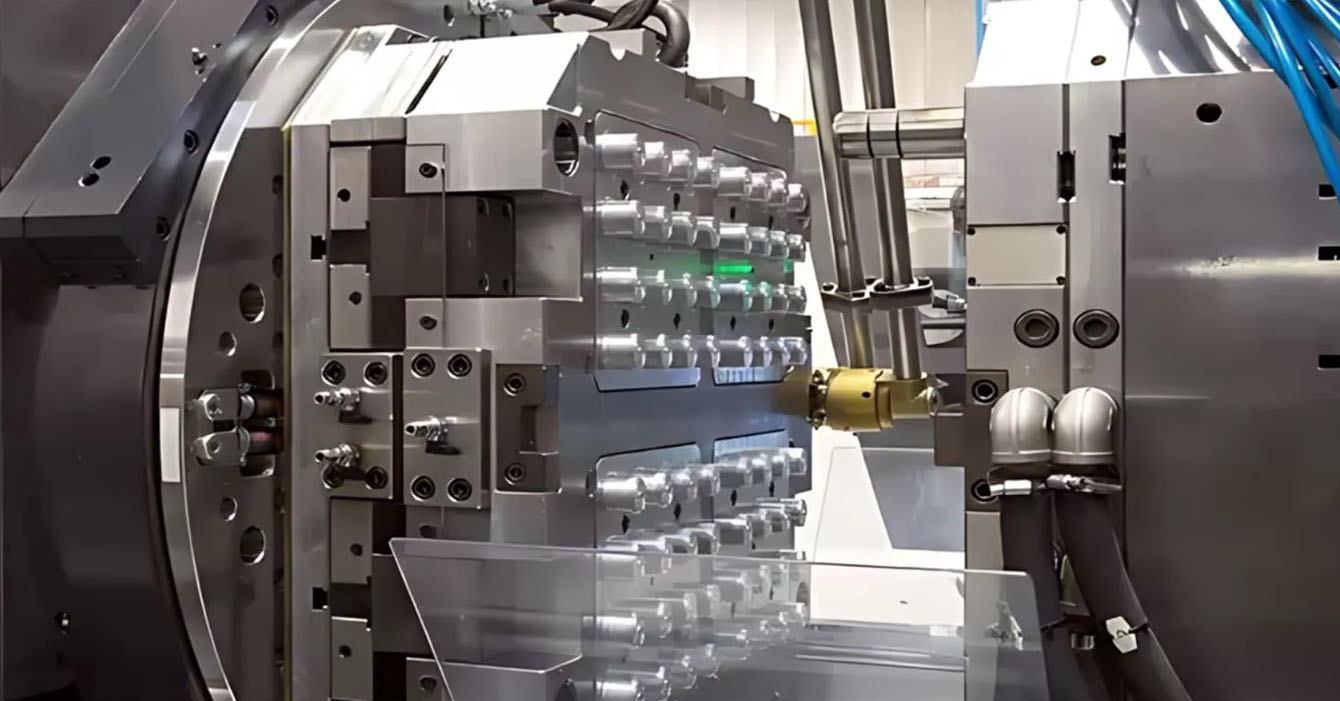

The 5 Golden Rules of Injection Mold Gate Design – From Single-Point to Multi-Point Hot Runner

Master injection mold gate design with 5 golden rules that prevent short shots, weld lines, and sink marks. Learn how to choose gate types, position them correctly, and balance multi-cavity molds for reliable custom injection molding. Boost first-shot success and cut cycle time today!

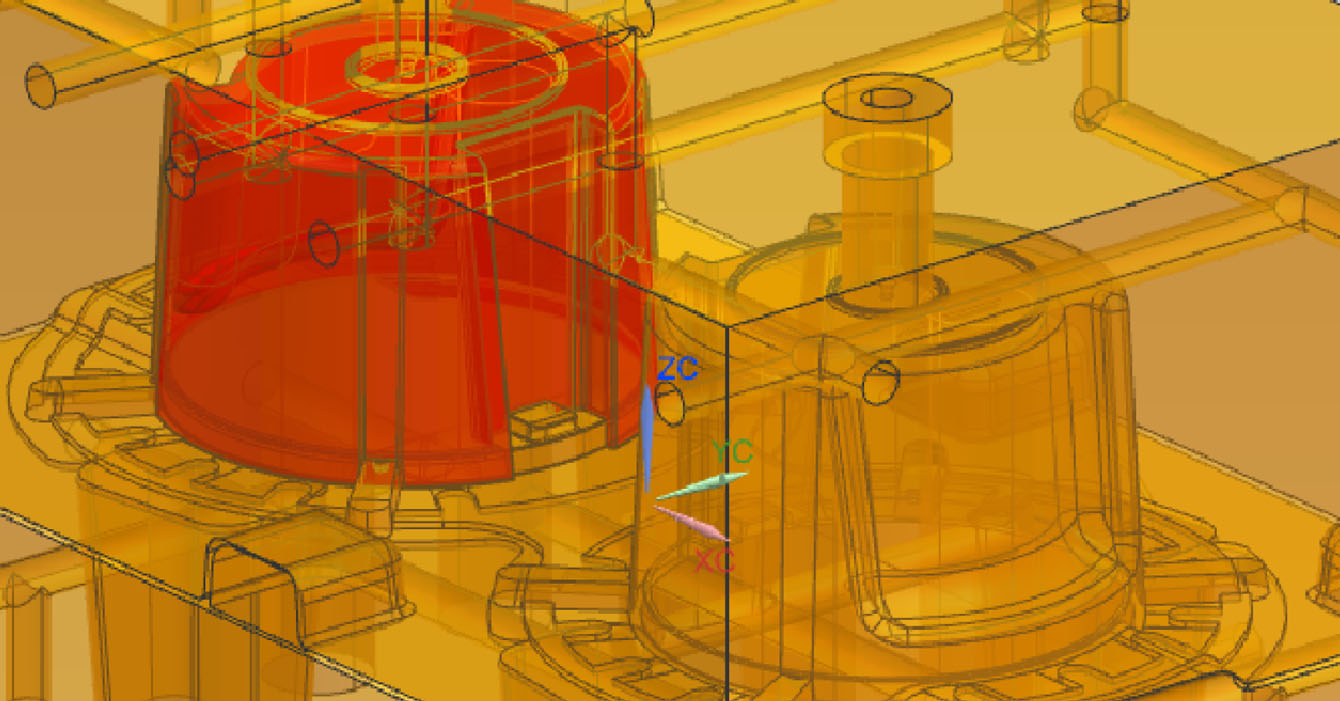

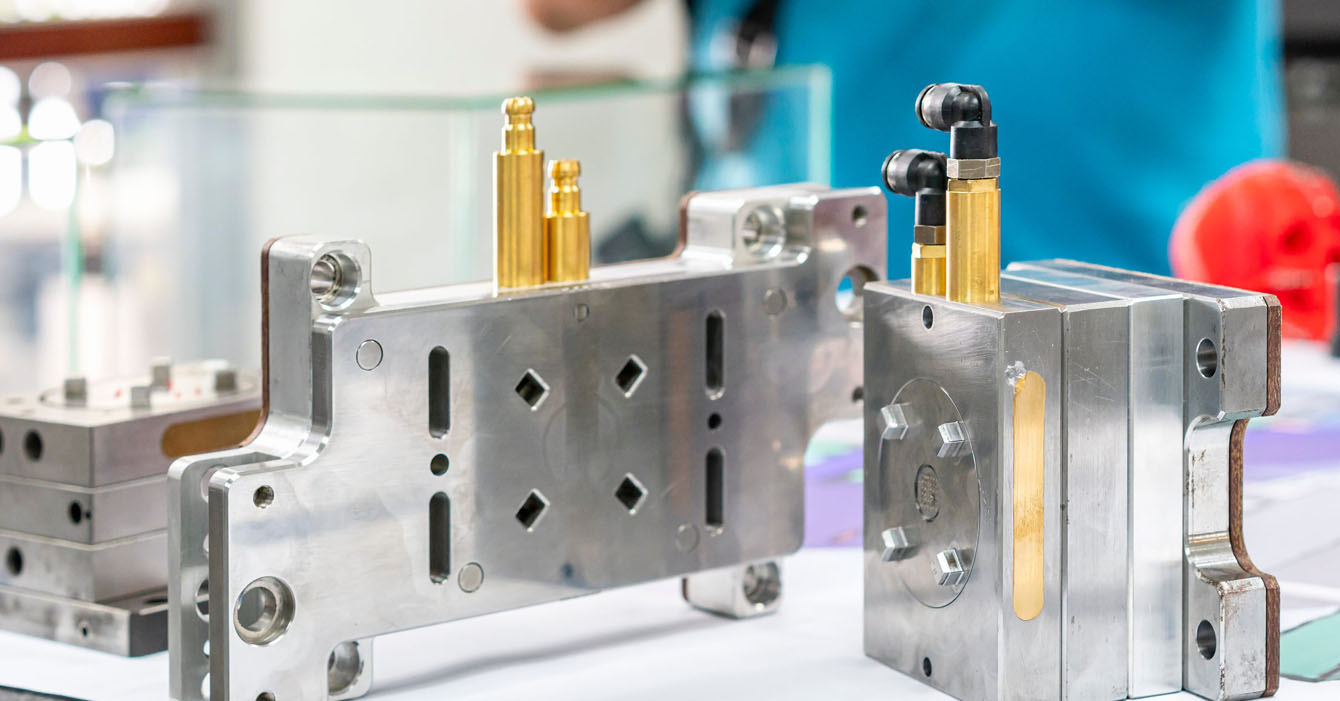

Die-Casting Mold Cooling Channel Design: Matching Steel to Water Flow

How to design mold cooling channels to extend lifespan? A seasoned engineer shares pro tips on pairing cooling systems with steel types (H13, 8407, DAC, etc.). Master spacing rules, temperature balance, and common mistakes to double mold longevity—applicable to both injection and die-casting molds.

Die-Casting Mold Steels: A Veteran Engineer’s Guide to Longevity

How to select die-casting mold core steel for durability? A veteran engineer reveals the secrets for aluminum (ADC12/zinc alloy) molds. Compare materials like H13, 8407, DAC, and SKD61, understand lifespan differences across production volumes (small-batch/mass-production/thin-wall), and learn from real cases to avoid “expensive but short-lived” steel choices.

How to Maintain Your Molds for Maximum Lifespan—Because Even the Best Design Needs Love!

Discover the ultimate mold maintenance guide to extend your mold lifespan 2-3x! Learn daily, weekly, and long-term care routines—from cleaning plastic residue to inspecting cooling channels—for injection and die-casting molds. Pro tips to avoid costly repairs and keep production running smoothly!

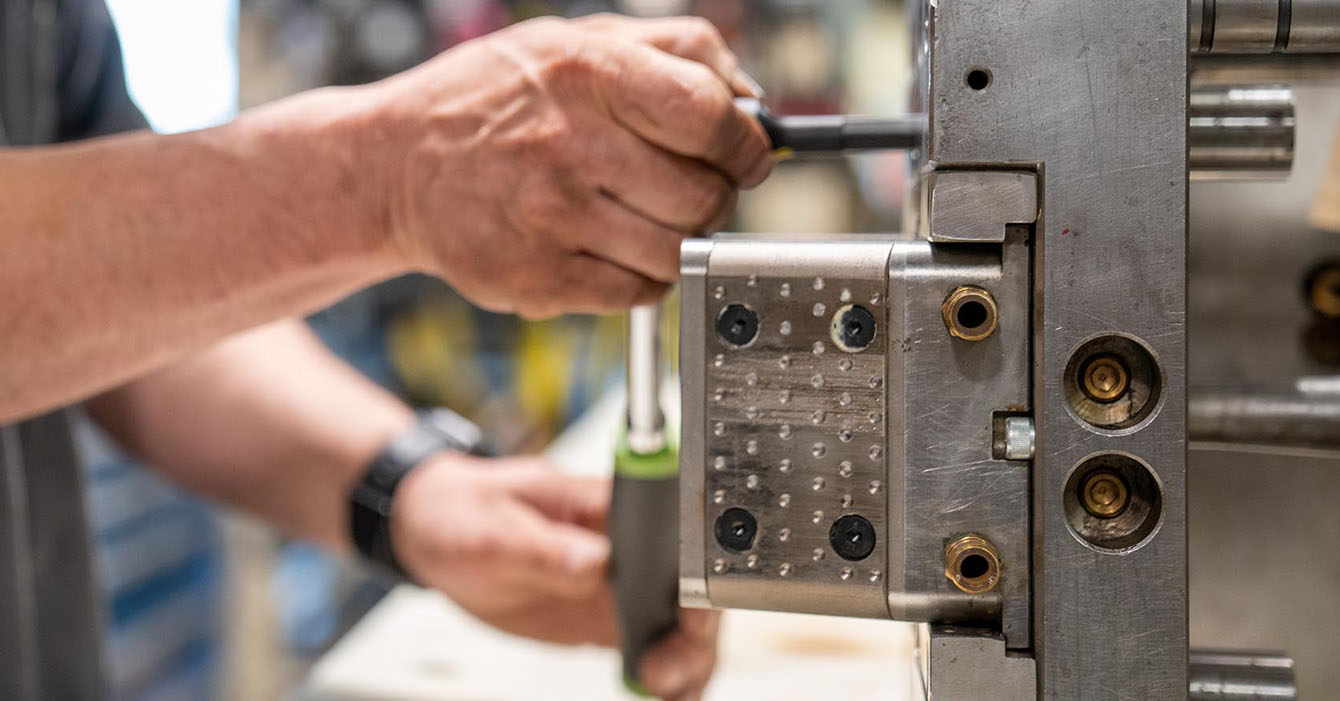

Injection Mold Core Steel Selection: A Veteran Engineer’s Guide to Lifespan & Best Practices

In the mold-making business for over a decade, I’ve seen too many clients fall into the same traps—wrong steel selection leading to rapid wear during mass production, or molds cracking after just a few thousand cycles. Today, let’s cut through the…